CHINA (en)

/1/

Definitions of

non-road mobile

machinery

Regulations in China cover the model year inspection, manufacturing, air pollutant emission, in-use inspection and durability of non-road mobile machinery (equipment or engines) (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

The type of machinery regulated includes machinery used in construction covering excavation, earthmoving, lifting machinery, forklifts, compactors, road construction and maintenance, machinery used for concrete, tunnelling, piling, aerial lift machinery, rock drilling machinery; agricultural machinery; airport ground handling equipment; loading and unloading equipment; snow ploughing equipment and industrial drilling equipment.

Within stationary machines or engines, the regulations cover air compressor equipment, generators, machinery used in fishing (aerators, pond diggers, etc.) and water pumps.

The definitions of NRMM can be found in the GB20891 (2014) regulation of the Ministry of Ecology and Environment of the People’s Republic of China, which states:

Non-road mobile machinery: “self-driven or double function; machinery self-driven and operating other functions; machinery which fails to be self-driven but is designed to be capable of moving or being moved from one place to another place. “.

Likewise, the same regulation GB20891 (2014b) of the Ministry of Ecology and Environment of the People’s Republic of China classifies non-road mobile machinery according to its power into:

Diesel engine: “engine with a power range below or equal to 560 kW”.

Gasoline engine: “engine with a power range below or equal to 19 kW”.

On the other hand, according to the mandatory regulation GB 19756 (2005) of the Ministry of Ecology and Environment of the People’s Republic of China, off-road machinery that is classified as a low-speed three-wheeled or four-wheeled vehicle is defined as:

Three-wheeled vehicle: “vehicles whose maximum speed is less than or equal to 50 km/h”.

Low-speed vehicles: “four-wheeled vehicles with a maximum speed of 70 km/h or less”.

In addition to the previously mentioned definitions of off-road machinery, regulation GB 20891 of the Ministry of Ecology and Environment of the People’s Republic of China sets out definitions for secondary engines as follows:

Secondary engine: “Diesel engine, which is mounted for road vehicle, does not provide driving force for vehicles but provides power for vehicle-mounted special facilities “.

/2/

Main regulatory

instruments for NRMM

emissions reduction

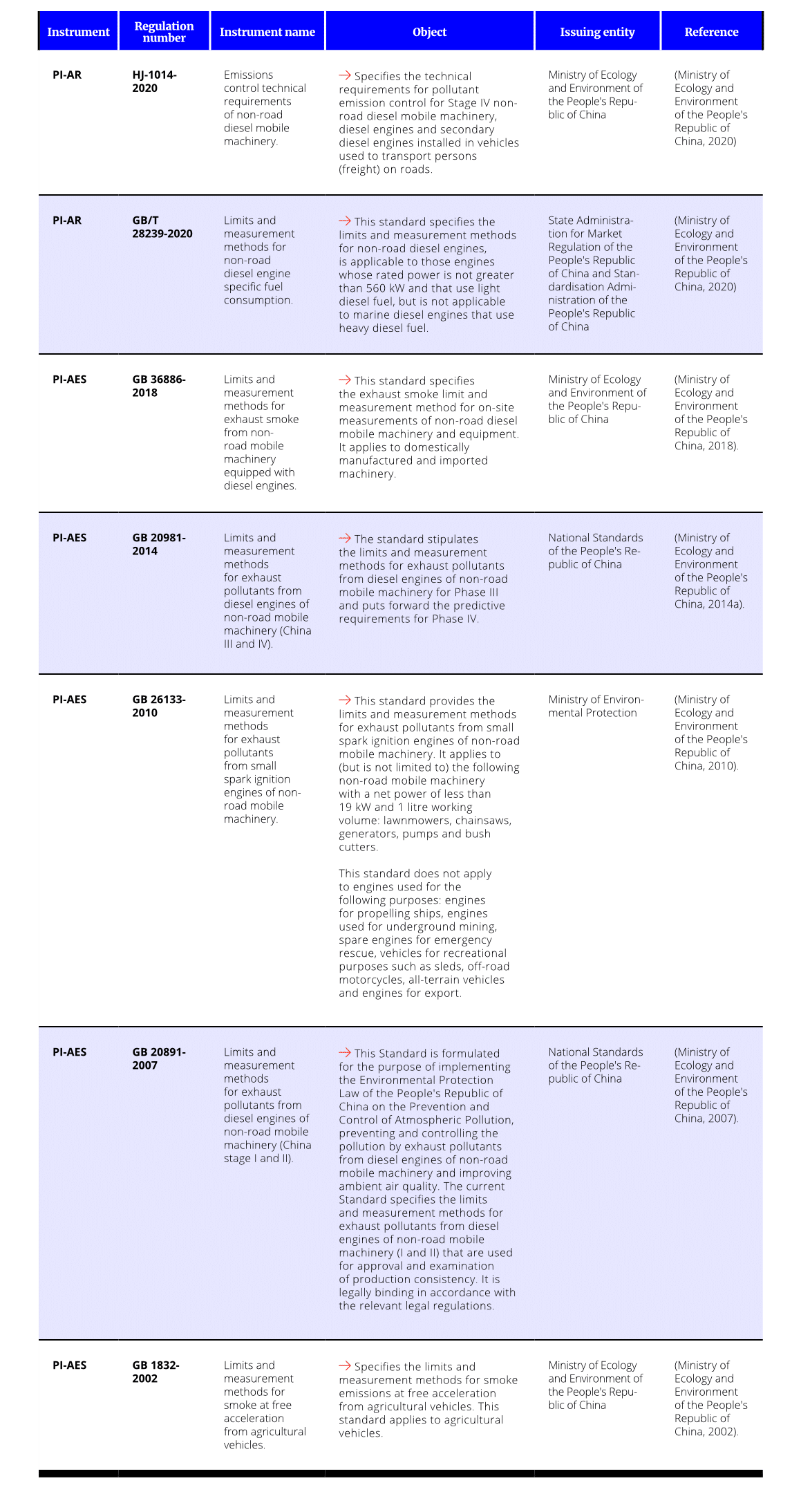

A compilation of different types of instruments identified in China for monitoring air pollution generated by NRMM is presented in Table 1.

Tabla 1

Regulatory framework and identification of tools for MMNC emissions reduction – China.

Fuente: elaboración propia.

In 2020, the Chinese government updated the regulations for NRMM emissions. The new standards, scheduled for implementation in December 2022, will be equivalent to Stage IIIB limits but enhanced to meet some requirements of the Euro Stage V standards (ICCT, 2021). Analysis available at: https://theicct.org/publications/china-iv-non-road-emission-standards-jul2021

/3/

Emission standards

for air pollutants

El decimotercer Plan Quinquenal de China sobre Protección Ecológica y Ambiental, mostró la intención de China de acelerar el diseño, revisión e implementación de estándares de emisión para vehículos no de carretera (non-road) (ICCT, 2017a), impulsando la incorporación del estándar China IV antes del año 2020, la cual presentaría una oportunidad de alinear los estándares chinos con los estándares norteamericanos Tier 4, además de incorporar tecnologías postratamiento de emisiones tipo DPF (Diesel Particle Filter).

In 2014 the Ministry of Ecology and Environment of the People’s Republic of China defined the limits and measurement methods for pollutants from NRMM diesel engines for the China III and IV standards (equivalent to the European Stage IIIA and Stage IIIB, respectively)

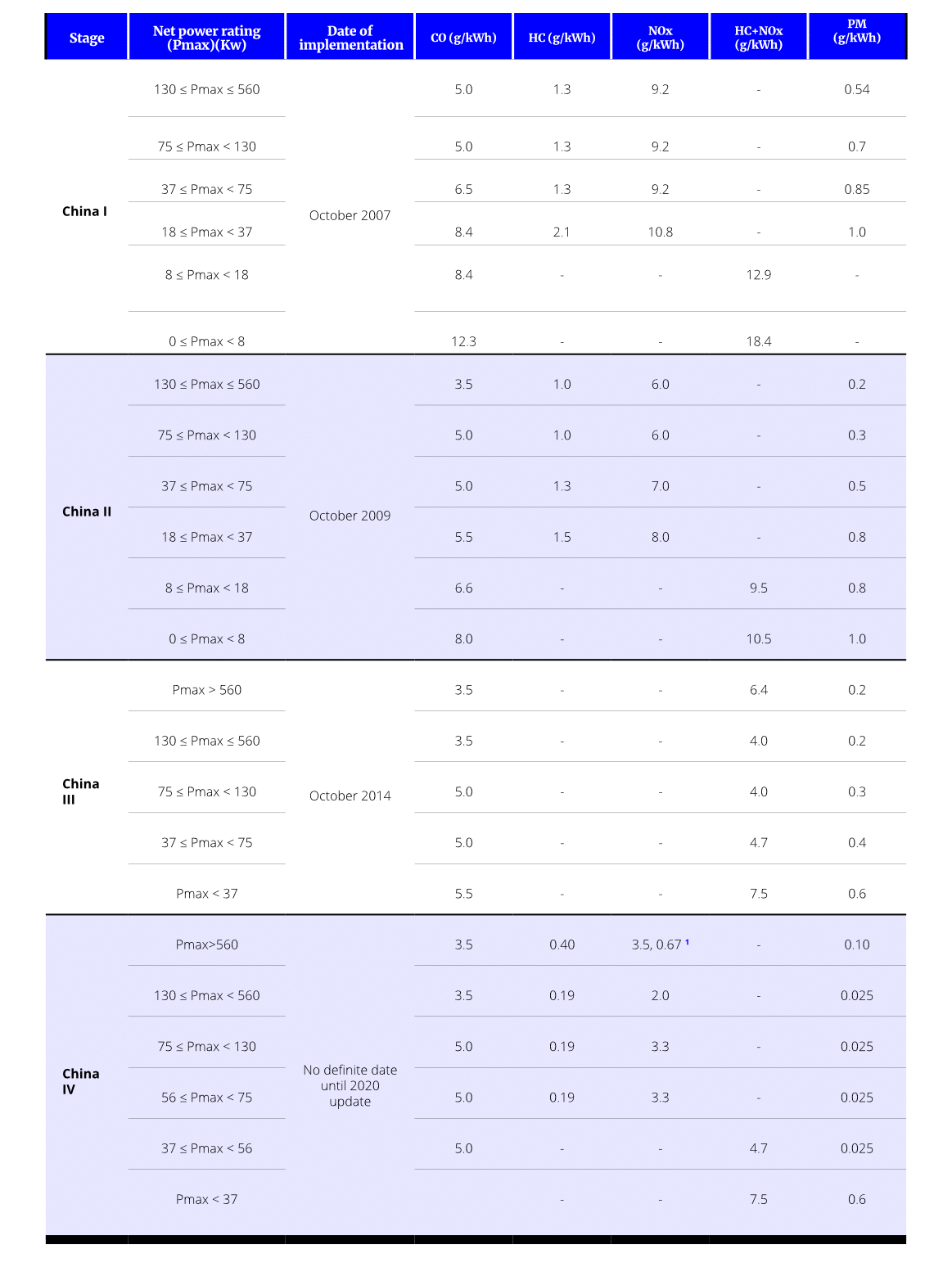

China has historically followed the implementations of European standards for NRMM emissions, starting with the China I and II standards, implemented since October 2007 and October 2009 respectively, as stipulated in regulation GB20891-2007 which included the description of pollutant measurement methods for NRMM diesel engines and which at the time were generally aligned with the EU Stage I and II standards determinations (ICCT, 2021).

Subsequently, in 2014 the Ministry of Ecology and Environment of the People’s Republic of China defined the limits and measurement methods for pollutants from NRMM diesel engines for the China III and IV standards (equivalent to the European Stage IIIA and Stage IIIB, respectively) according to the GB 20891-2014 regulation. However, although the gradual implementation of the China III standards would start from October 2014, the implementation date for the China IV standards had not been defined until the amendment or update of their regulation that occurred in 2020, where these China IV standards are scheduled to be required from December 2022 and will be equivalent to the European Stage IIIB but with updates that include, in addition to emission limits for NH3 and PN, the use of portable emission measurement systems (PEMS) during engine operation, NOx and particulate control diagnostic systems (NCD and PCD respectively), installation of GPS systems, remote emission monitoring for equipment between 37 and 560 kW and labelling requirements for NRMM as described in the ICCT report The updated China IV non-road emission standards (ICCT, 2021), so as to meet some of the requirements that characterise the Stage V standards currently being implemented for the European Union.

The emission limits for criteria pollutants for non-road mobile machinery according to the regulations GB 36886-2018, GB 20891-2014, GB 26133-2010, GB 20891-2007 and GB 19756-2005 are given in the tables below (Ministry of Ecology and Environment of the People’s Republic of China, 2005, 2007, 2010, 2014b, 2018)..

Emission limits for Stage I, II, III and IV non-road mobile machinery engines:

The limits reported by the GB 20891-2014 and GB 20891-2007 regulations are shown in the table below.

Tabla 2

MMNC Diesel Engine Exhaust Pollutant Emission Limits.

Fuente: Ministry of Ecology and Environment of the People’s Republic of China, 2007, 2014b

Tabla 3

New MMNC diesel engine exhaust pollutant emission limits according to China IV standard updated in 2020 for implementation from 2022.

Source: (ICCT, 2021)

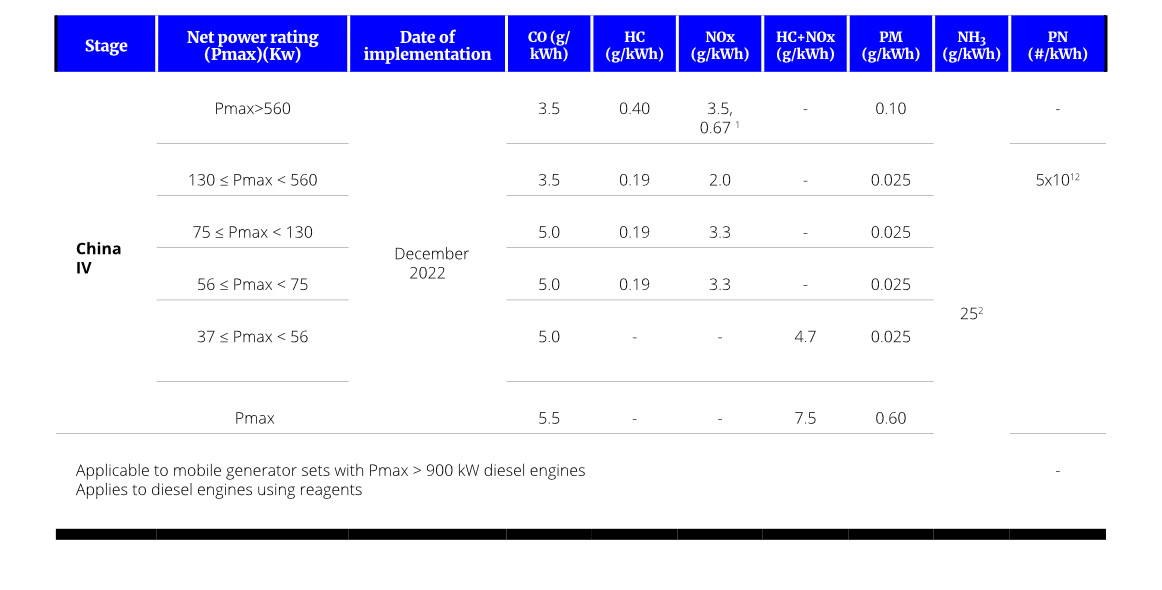

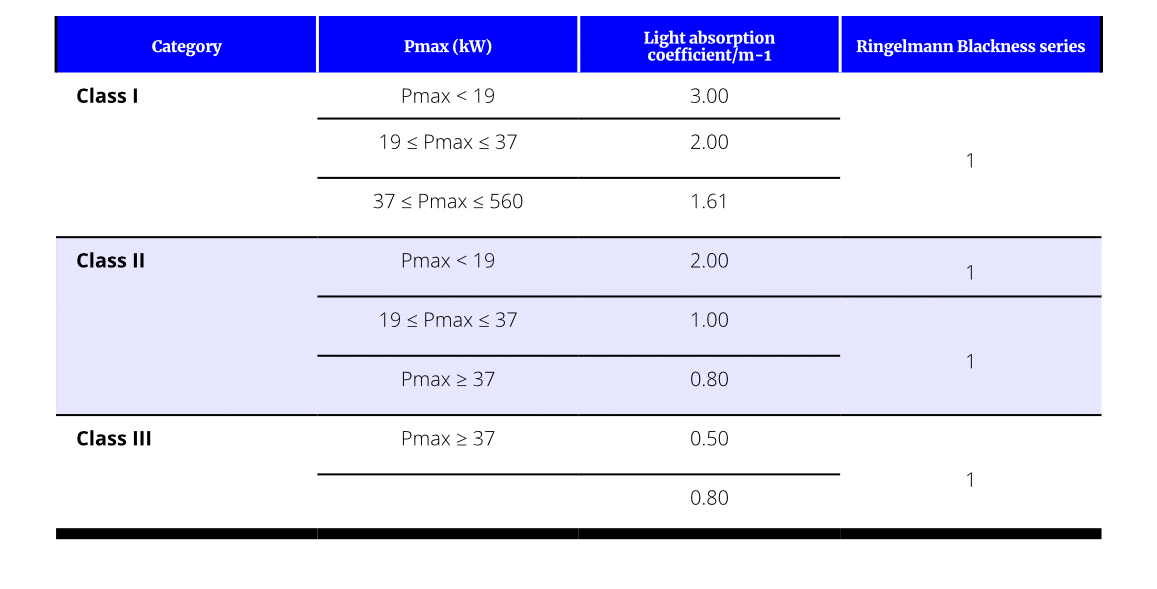

Exhaust emission limits for non-road mobile machinery:

The limits of regulation GB 36886-2018 are presented below:

Tabla 4

Limits and methods of measurement of exhaust fumes from non-road mobile machinery equipped with a diesel engine.

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2018).

Tabla 5

Engine category.

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2018).

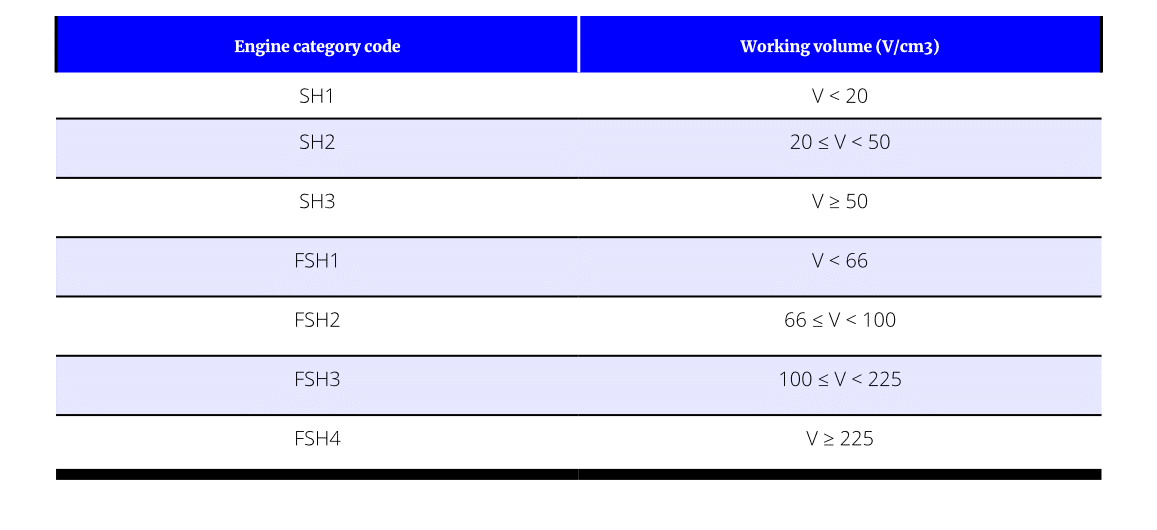

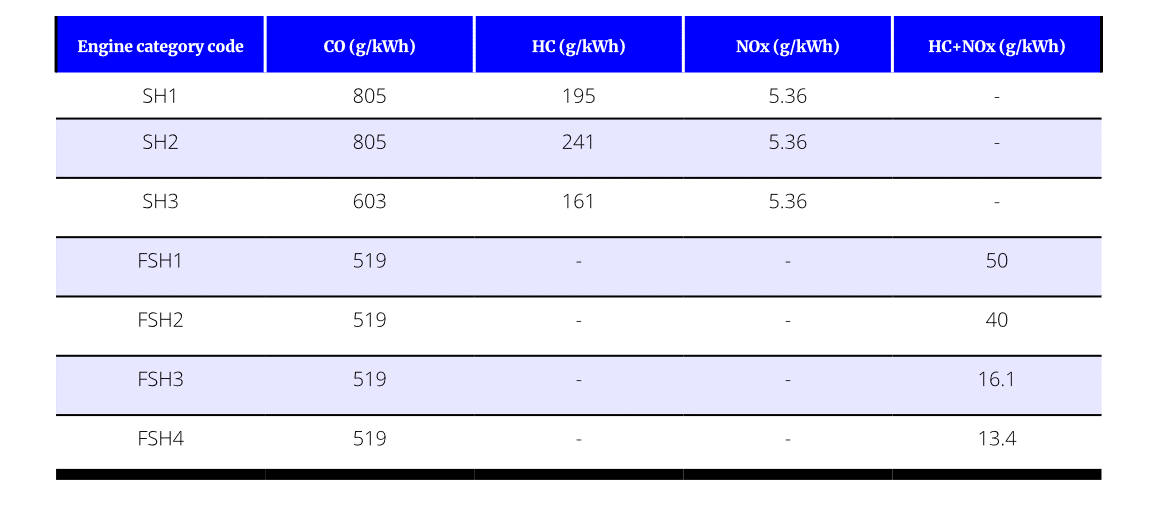

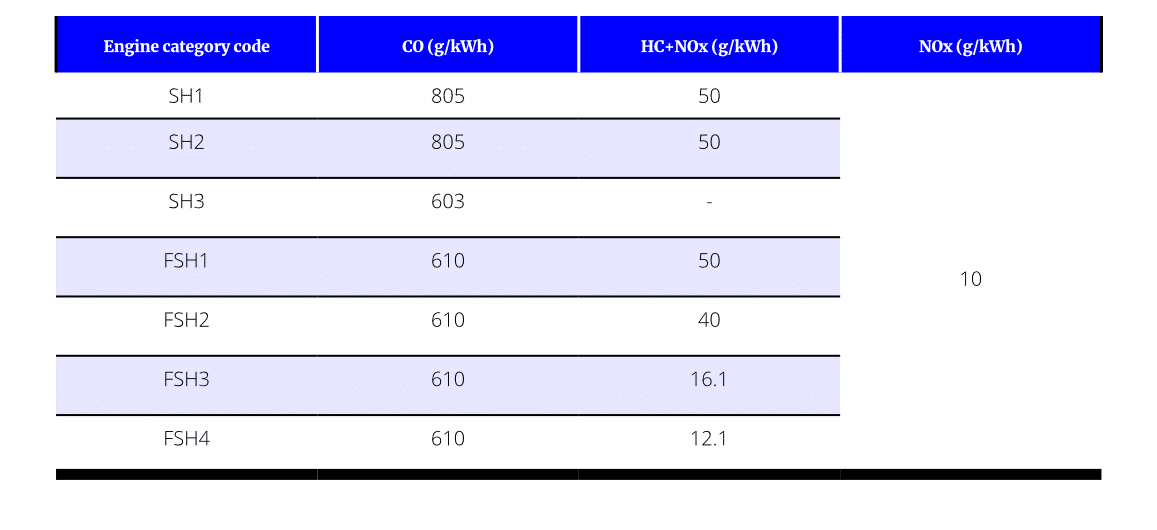

Stage I and II emission limits for small SI engines:

The emission limits of the GB 26133-2010 regulation are presented in the following tables.

Tabla 6

Engine exhaust pollutant emission limits (Stage I).

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2018).

Tabla 7

Engine exhaust pollutant emission limits (Stage II).

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2018).

Criteria for defining emission limits

The Air Law (Law on the Prevention and Control of Air Pollution, 2000) mentions the need to improve air quality by emphasising the treatment of emissions from a prevention perspective and mentioning non-road mobile sources as sources of concern. Manufacturers and importers of machinery with power ratings less than or equal to 560 kW shall comply with the requirements of regulation HJ 1014-2020. The law promotes efforts to reduce pollutants such as particulate matter (PM), sulphur dioxide (SO2), nitrogen oxides (NOx), volatile organic compounds (VOC), ammonia (NH3) and greenhouse gases. Furthermore, due to the country’s economic growth in the construction/1/ sector and the agricultural/2/ sector , the relevance of incorporating emission standards for the equipment used by these sectors was noted.

According to the Environmental Protection Tax Law of the People’s Republic of China (Standing Commite of the National People’s Congress, 2016), Article 12 of Chapter III entitled “Tax Reduction and Exemption”, in sub-index ii, states that pollutants discharged by mobile sources such as railway locomotives, ships and aircrafts shall be exempted.

/4/

Import requirements

and type-approval

processes

4.1 Manufacturing and import requirements

The NRMM manufactured or imported shall report the information set out in the GB 20891-2014 regulation (Ministry of Ecology and Environment of the People’s Republic of China, 2014b), specifically in Annex A of the standard. Likewise, manufacturers and importers of machinery with power ratings less than or equal to 560 kW shall comply with the requirements of regulation HJ 1014-2020.

In general terms, manufacturers will have to comply with the emission standards defined in the current regulation, as well as provide precise information on how to operate the engines that will be destined for NRMM, either through manuals containing information related to the installation of emission control systems, global positioning systems, as well as obligations regarding preventive measures for the dismantling of engine parts (Ministry of Ecology and Environment of the People’s Republic of China, 2020). In that regard, the general obligations of manufacturers are summarised as follows:

- Type of fuel to be used by the engine/3/ .

- Reporting of emissions to environmental authorities when machinery is fitted with control systems, as well as NOx emissions when not fitted with such systems (HJ 1014-2020 section 5.1.6).

- Emission control systems (reactants) (HJ 1014-2020 section 5.6.1).

- Manuals for operating emission control systems (HJ 1014-2020 section 5.6.5).

- Maintenance instructions.

- Preventive measures (HJ 1014-2020 section 5.7.3).

- Use and reporting of engine global positioning system failures (HJ 1014-2020 section 5.7.4 and 5.7.7).

- Warranty periods (HJ 1014-2020 section 5.8.3).

- Voluntary self-inspections (HJ 1014-2020 section 7.2.2).

- Report which types of engines belong to the same family.

According to HJ 1014-2020, section 5.7.4: The NRMM with a rated net power of 37 kW or higher shall be equipped with satellite navigation precision positioning systems before leaving the factory, and shall meet the requirements of section 5.7.7. (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

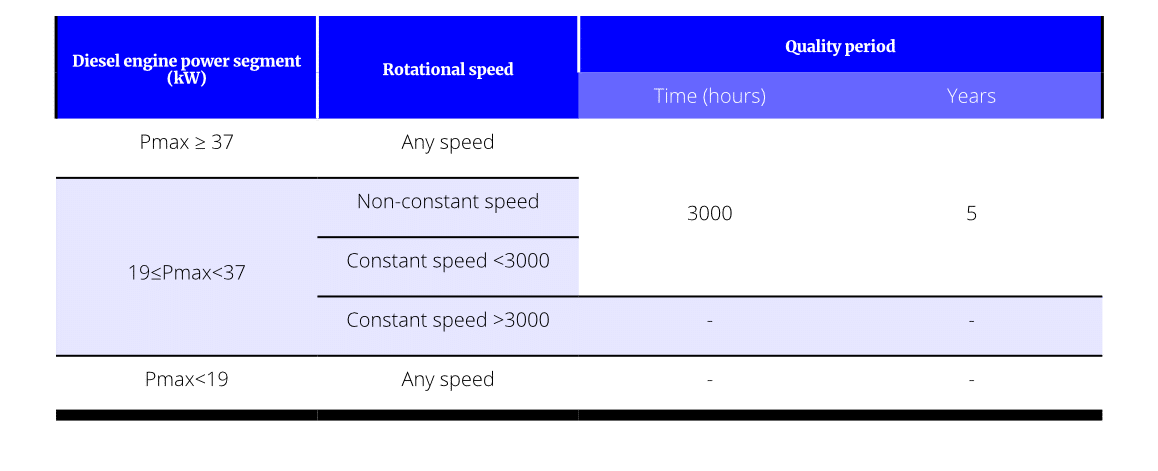

With regard to the warranty periods, as specified in Annex B of GB 36886-2019, the manufacturer shall provide the emission-related components in accordance with HJ 1014-2020, section 5.8.3. (Ministry of Ecology and Environment of the People’s Republic of China, 2020). This period shall not be less than the periods specified in table below.

Tabla 8

Requirements for key environmental protection components during the emissions warranty period.

* Warranty period is calculated from the date of sale.

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

4.2 Type-approval processes

According to the regulation HJ 1014-2020 and GB20891-2014 (Ministry of Ecology and Environment of the People’s Republic of China, 2014b, 2020), the definitions of the test and type-approval cycles are:

Test cycle: “Procedures that diesel engines are tested according to, with defined speed and torque under steady state or transient state (NRTC, Non-road transient cycle) conditions”.

Non-road steady cycle: “Test cycles comprising 5, 6 and 8 cycles for the measurement of combustion emissions for Stage III and Stage IV diesel engines”.

NRTC test: “Test cycle consisting of 1238 gradual changes of working conditions”.

The NRMM equipped with diesel engines, with rated net power from 37 kW to 560 kW, shall be equipped with diesel particulate filter (DPF) or more efficient particulate removal control system. When testing according to the procedures defined in regulation GB 20891-2014 and HJ 1014-2020 (Annex B in both regulations), the particle number results obtained shall be multiplied by the deterioration factor. The final results shall not exceed the limits set by GB 10891-2104 and shall not show visible smoke during the test (Ministry of Ecology and Environment of the People’s Republic of China, 2014b, 2020).

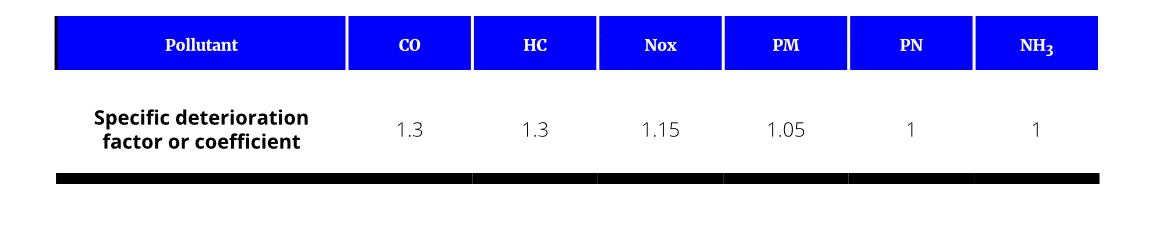

The deterioration factors according to the 2020 update for the China IV standards that would come into effect from 2022 were generated based on tests of diesel engines in actual operation and will correspond to 1.3 for CO, 1.3 for HC, 1.15 for NOx, 1.05 for PM, 1.0 for PN and 1.0 for NH3. The proposal of these deterioration factors is intended to potentially reduce manufacturers’ testing costs, so that manufacturers would make use of their application directly rather than determining equipment durability test values, which would normally require them to test their engines The NRMM equipped with diesel engines, with rated net power from 37 kW to 560 kW, shall be equipped with diesel particulate filter (DPF) or more efficient particulate removal control system. over a representative duty cycle (under actual operating conditions that would include driving and performing work such as lifting) of a quarter or more of the full service life (ICCT, 2021).

According to HJ 1014.2020 (2020) type-approval tests are performed on dynamometers with steady state/4/ and transient state cycles/5/. The variables to be considered during the tests include absolute temperature (Ta) of the diesel engine at the inlet expressed in Kelvin (K); dry atmospheric pressure (Ps), expressed in kPa and the laboratory atmospheric pressure factor to be calculated following the formulae in Annex B, section B.2.2.1. Other types of tests performed are durability tests, NOx control and PM control. A summary of the type of tests performed is described in the table below.

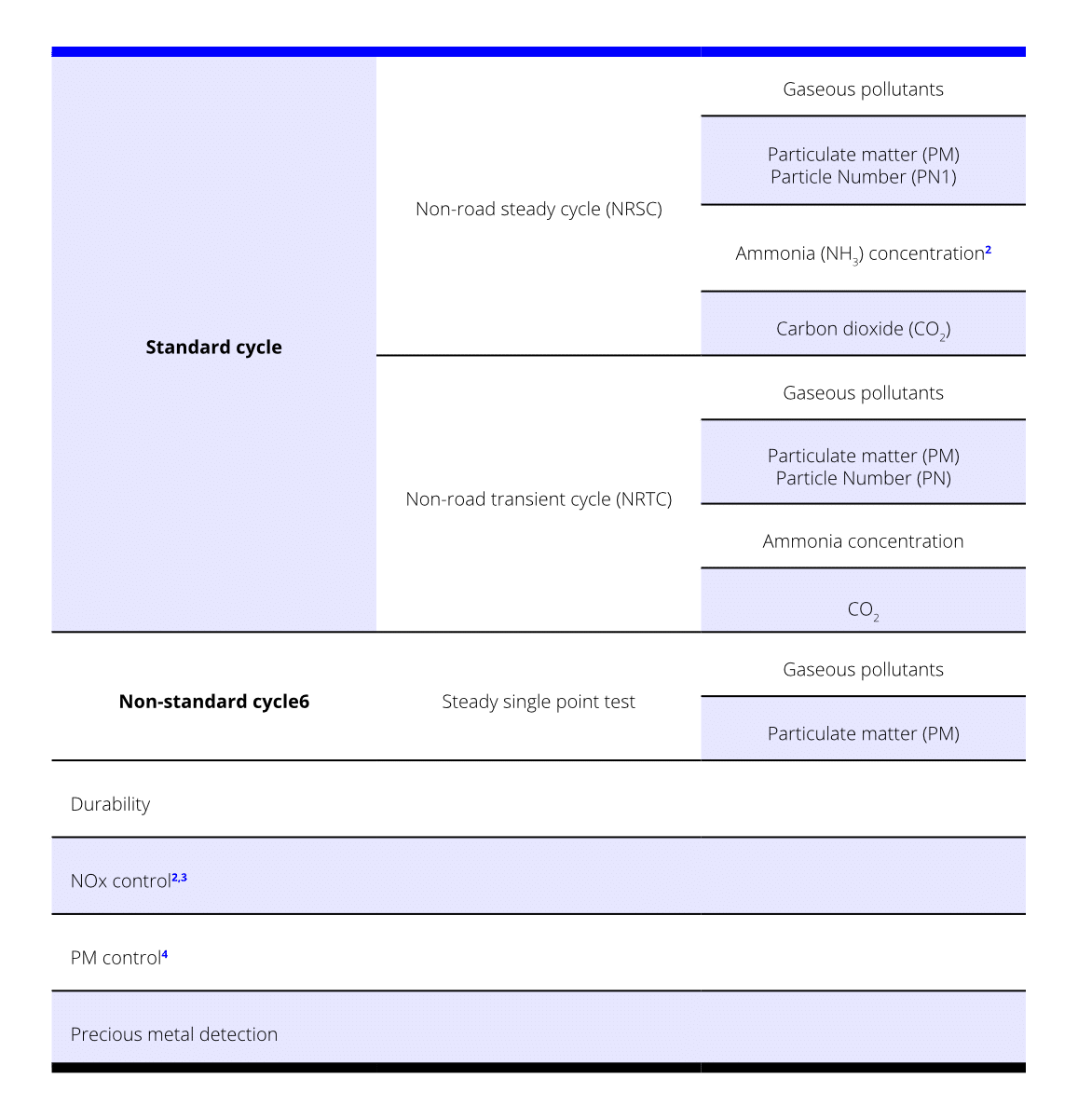

Tabla 9

Types of tests carried out in the approval processes.

Durability

NOx control2,3

PM control4

Precious metal detection

1PN measurements suited to 37kW<Pmax<560kW diesel engines.

2Test items requiring use of reactant aftertreatment system.

3Test items requiring use of EGR system.

4Test items requiring use of particulate matter aftertreatment system.

5Does not apply to Pmax< 19 kW single-cylinder diesel engine.

6Applies to diesel engines with electronic fuel injection systems.

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

/5/

Labelling

processes

According to the regulation HJ 1014-2020 (2020) all diesel engines must carry a label which must comply with the following parameters:

- The label shall not be removed from the engine, unless due to engine deterioration the label is not visible.

- The label shall remain legible during the entire life of the diesel engine.

- It shall be located in a place that does not interfere with the free operation of the engine.

- The location of the label shall be clearly visible.

If the label cannot be positioned in a visible place for any reason, the manufacturer shall provide an additional label which cannot be removed from the machinery and which does not interfere with the operation of the machinery.

The information on the label must comply with the following specifications:

- The label shall display the words “environmental information label”.

- Power section corresponding to the standard defined in Article 5.2.3 and approval number described in Annex F.

- Type, engine family and power.

- Date of engine manufacture: year, month and day. If the engine already contains the date of manufacture, the label may discard this information.

- Full name of manufacturer.

- Technical information on control systems: ECU, NCD, PCD, EGR turbocharger, intercooler, fuel injection pump, fuel injector, DOC, DPF, SCR, air filters, intake muffler, exhaust muffler, etc.

- Basic information: machine manufacturer’s name, machine name, trademark, machine type, model, engine manufacturer’s name, engine model, fuel injection system type, etc.

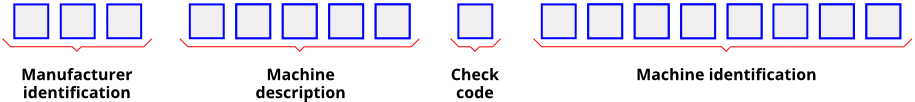

Each machine shall have a 17-digit alphanumeric environmental identification. For machines used in earthmoving tasks, the product identification number (PIN) shall be reported in accordance with GV/T25606-2010 and ISO 10261:2002 (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

The rules for the definition of the numerical environmental identification shall be as follows: manufacturer identification part + machinery description part + check digit + machinery identification part (Figure 8. 3).

FIGURE 1

Numbering diagram for machinery environmental identification numbers

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

FIGURE 2

Format of the environmental identification number that machinery must use

Fuente: Ministry of Ecology and Environment of the People’s Republic of China, 2020.

A detailed description of the content of each of the alphanumeric digits can be found in Annex K of HJ 1014-2020.

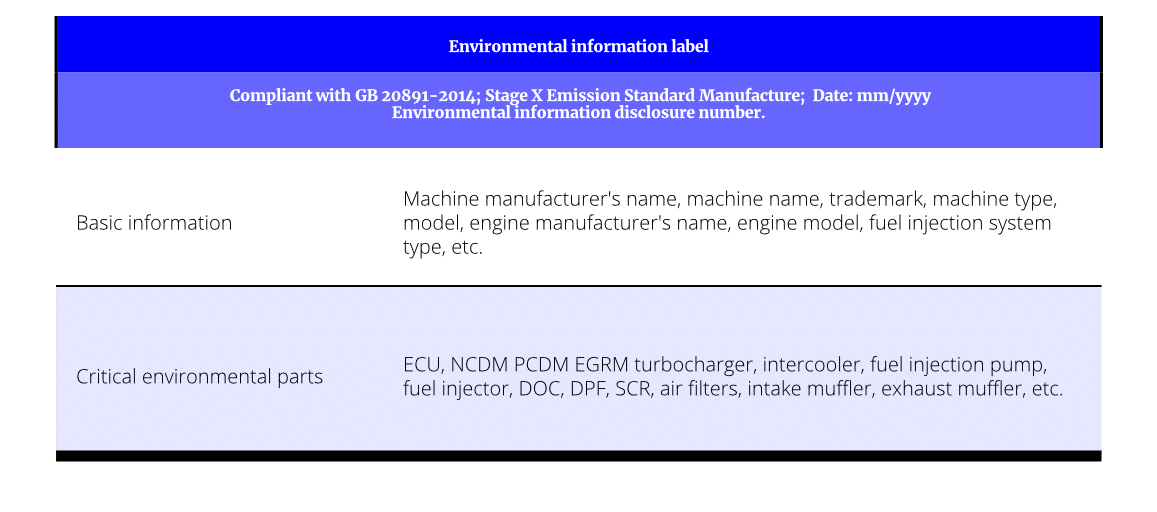

The size of the label can be 130 mm x 60 mm. The content of the label must be legible. Some label examples are shown in the following tables.

Tabla 10

Example 1: Environmental information label format of MMNC in China.

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

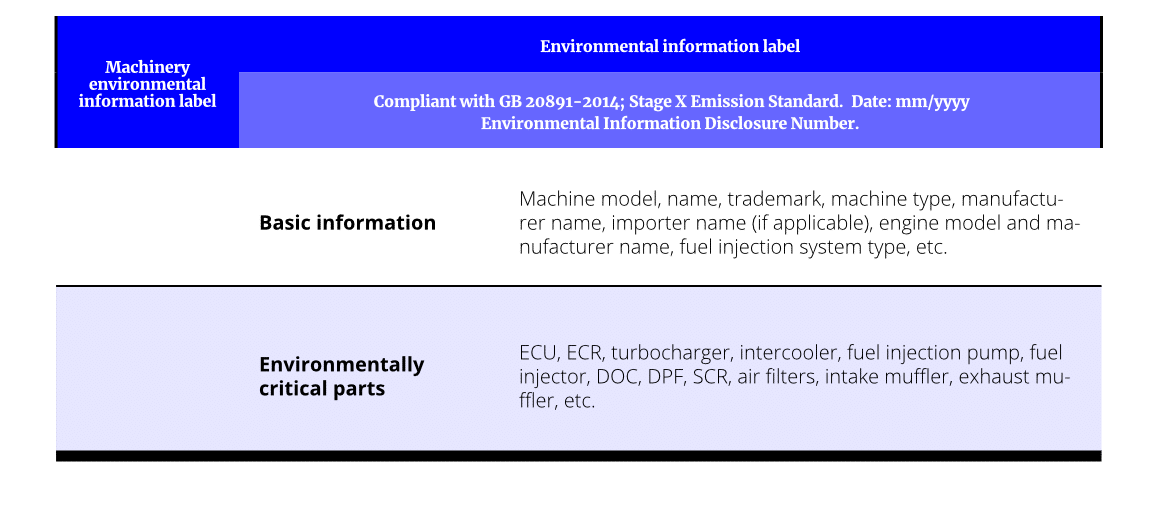

Tabla 11

Example 2: Environmental information label format of MMNC in China.

Fuente: Ministry of Ecology and Environment of the People’s Republic of China, 2020.

/6/

Regulation on machinery

useful life, repowering, overhaul and

scrapping practices

The maximum useful life of machinery is specified in Article 5.2.2 of GB 20891-2014. It ensures the normal operation of NRMM diesel engines and their emission control systems (if any) to comply with the emission limits for gaseous and particulate pollutants and has been confirmed in the type-approval (Ministry of Ecology and Environment of the People’s Republic of China, 2014b).

The durability tests of diesel engines are performed according to the parameters set out in Annex BD of GB 20891-2014 where the respective deterioration factor or coefficient, generated on the basis of tests of diesel engines in actual operation, is determined. The tests shall be performed according to the test cycle defined in Annex BD.2.1. (Ministry of Ecology and Environment of the People’s Republic of China, 2014b).

As of January 2019, only diesel engines that meet the China IV fuel quality standard can be sold in the territory.

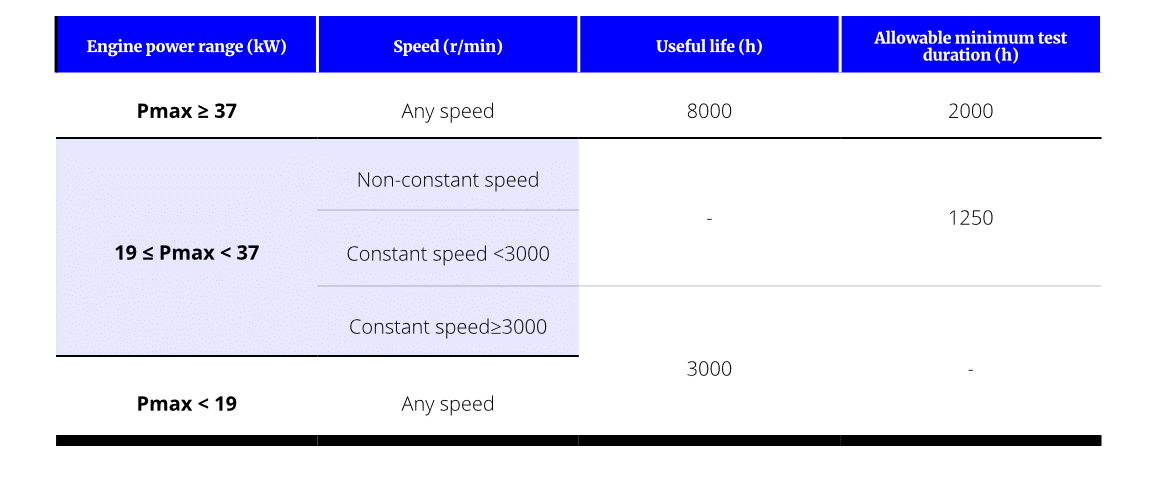

The engine durability test times according to GB 20891-2014 regulation shall not be lower than 25% of the diesel engine useful life time specified in Table 9.3 (Ministry of Ecology and Environment of the People’s Republic of China, 2014b). On the other hand, the entity performing the durability tests may randomly choose the type of test that fits the times defined in the table below.

Tabla 12

Durability time requirements.

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

Tabla 13

Specified deterioration coefficient or factor of each contaminant.

Source: (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

Diesel engine manufacturers shall be permitted to choose the deterioration coefficient specified in the above table as a substitute durability deterioration coefficient. The specific emissions of various pollutants shall be multiplied by the determined deterioration coefficients, and the results shall not exceed the limits specified in regulation GB 20891-2014.

Regulation HJ 1014-2020 adds criteria for determining the deterioration coefficients for diesel engines:

The use of one of the two test cycles of GB 20891-2014 No. B.3.8.1 and B.3.8.2 (hot start cycle only) shall be permitted at each time node to determine the deterioration coefficient or deterioration correction value, and the other test cycle shall require that an emission test be conducted at the beginning and end of the durability test. The determined deterioration coefficient or degradation correction value shall apply to the two cycles, and no pollutant emission at any node in the durability test shall exceed the limit specified in GB 20891- 2014 (Ministry of Ecology and Environment of the People’s Republic of China, 2020).

/7/

Operational and road

circulation requirements

7.1 Fuel quality operating requirements

The country independently regulated the sulfur content of diesel used in road and non-road machinery (Yang, 2021). Generally, fuel intended for non-road machinery contained high levels of sulfur, the Ministry of Ecology and Environment of the People’s Republic of China is the entity in charge of formulating and implementing national ecological and environmental policies, as well as responsible for drafting laws and regulations. low cetane index and lower lubricity/7/. In 2018, the State Council of China published the National Blue-Sky Plan, which standardized the quality of diesel used in both machinery sectors. In that sense, as of January 2019, only diesel engines that meet the China IV fuel quality standard can be sold in the territory.

7.2 Safety operation requirements

The Safety Standard of Machinery and Equipment (Safety Standard of Machinery and Equipment, 2014) states the following:

With regard to the operating requirements for forklift, ram and other machinery intended for loading goods, the following guidelines shall be met:

- There should be no significant damage or corrosion to machinery.

- The stress in the fork shall be below one third of the yield strength of steel used in the fork, when the maximum load is put in the base-load centre.

- When the forklift truck is equipped with a driver seat in a lifting manner, an armrest and a fall prevention device shall be provided.

- The seat cushion shall be made of shock-absorbing materials to prevent significant vibration of the body of the driver when the truck is moving.

- The type of forklift truck shall be equipped with safety belts, guard rails or other protective devices that prevent the driver from crushing when the truck falls.

Other requirements identified are as follows:

- The vehicle shall be explosion-proof.

- The vehicle shall comply with the requirements of CNS 4782.

/8/

Procedures for NRMM

control and inspection

in the operation stage

(No information for China)

/9/

Actors in import processes, manufacturing, registration, marketing, control and final practices of useful life of the MMNC

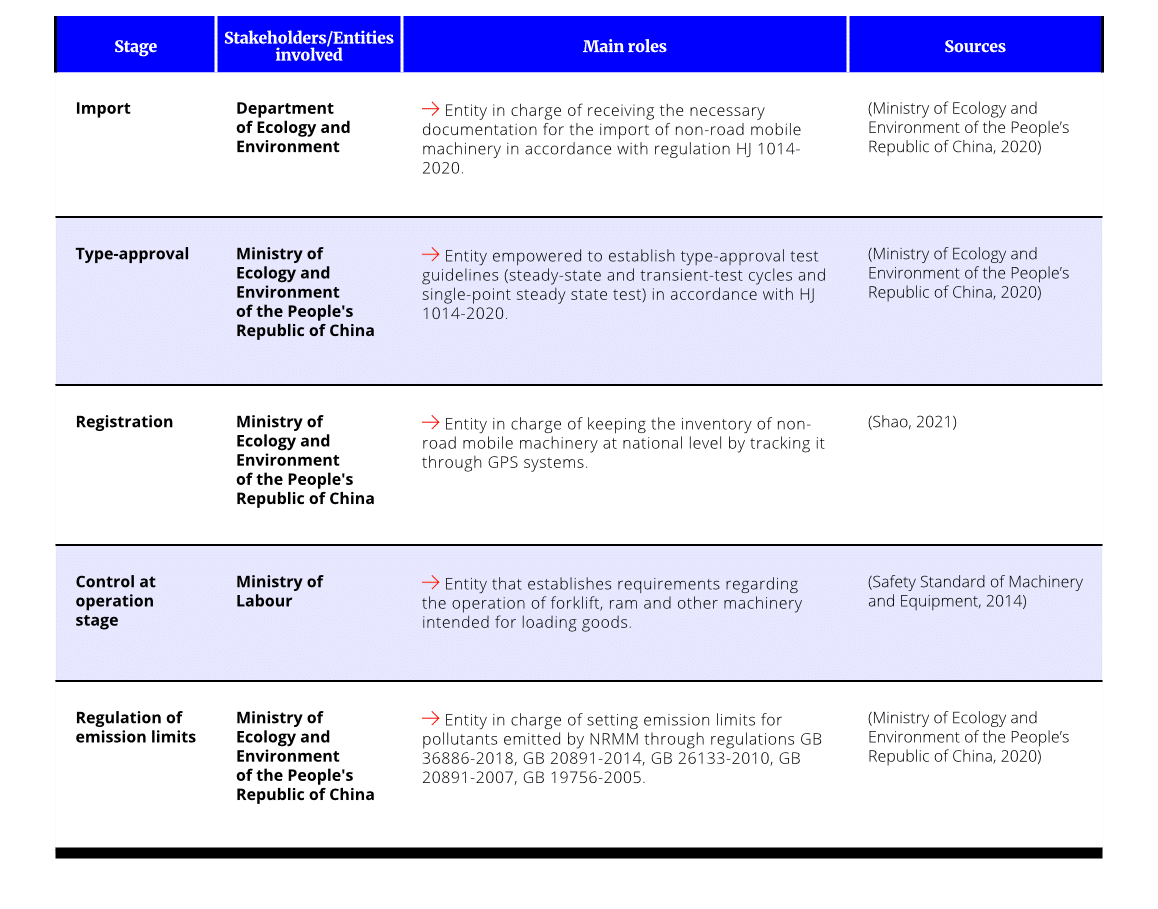

The table below presents the main stakeholders involved in NRMM processes in China. Complementary aspects of these processes are presented below.

Tabla 14

Stakeholders and roles – China.

Import

Machinery manufactured or imported shall report the information set out in GB 20891-2014 (Ministry of Ecology and Environment of the People’s Republic of China, 2014), specifically Annex A of the standard. Manufacturers and importers of machinery with a net rated power of 560 kW or below shall comply with the requirements of regulation HJ 1014-2020.

Type-approval

The Ministry of Ecology and Environment of the People’s Republic of China, in regulation HJ 1014-2020 and GB20891-2014) defines the testing and type-approval cycles.

Registration

The Ministry of Ecology and Environment is the entity where emission standards inspection processes are registered.

Control and inspection

On a general level, the Ministry of Ecology and Environment of the People’s Republic of China is the entity in charge of formulating and implementing national ecological and environmental policies, as well as responsible for drafting laws and regulations. Together with other departments, it supervises the implementation of ecological and environmental plans, organises and formulates ecological standards, as well as elaborates environmental technical specifications. According to the Environmental Protection Law of the People’s Republic of China, governments at or above the provincial level shall perform management and supervision tasks related to environmental protection management (Standing Committee of the National People’s Congress, 2016).

Consultation documents (downloadable)