USA

/1/

Definitions of

non-road mobile

machinery

The definition and regulation related to non-road mobile machinery is mainly based on the criteria of portability and mobility of the equipment on which the engines are installed. The regulation set forth in Chapter 40 of the Code of Federal Regulations (CFR) states, in different parts of it, that a non-road engine corresponds to any type of internal combustion engine that meets any of the following three characteristics:

- It is (or will be) used in or on a piece of equipment that is self-propelled or serves a dual purpose by both propelling itself and performing another function (such as garden tractors, bulldozers, etc.).

- It is (or will be) used in or on a piece of equipment that is intended to be propelled while performing its function (such as lawnmowers).

- By itself or in or on a piece of equipment, it is handheld or portable, meaning designed to be and capable of being carried or moved from one location to another.

Por fuera de esta definición se encuentran los motores que cumplan cualquiera de los siguientes criterios:

- The engine is used to propel a motor vehicle, an aircraft, or equipment used solely for competition.

- The engine is a stationary power source and is regulated under 40 CFR 60.

- The equipment remains at a location for more than 12 consecutive months, or a shorter period for an engine located at a seasonal source. A seasonal source is a stationary source that remains in a single location on a permanent basis and that operates at that single location approximately three months each year.

The following equipment is categorically outside the definition of the aforementioned regulations:

- Aircraft equipment.

- Mining equipment. Mining machinery is regulated by the Mining Safety and Health Administration in 30 CFR Mineral Resources. 40 CFR § 1039.5 states that this equipment is excluded.

- Locomotives, which are regulated by 40 CFR 92.

- Navigation equipment, regulated by 40 CFR 94.

- Hobby equipment/2/ : Small-scale models not suitable for transporting a person.

The definitions and regulations are further subdivided on the basis of the following properties:

- Compression ignition combustion engines are classified according to the rated power in units of kilowatts (kW).

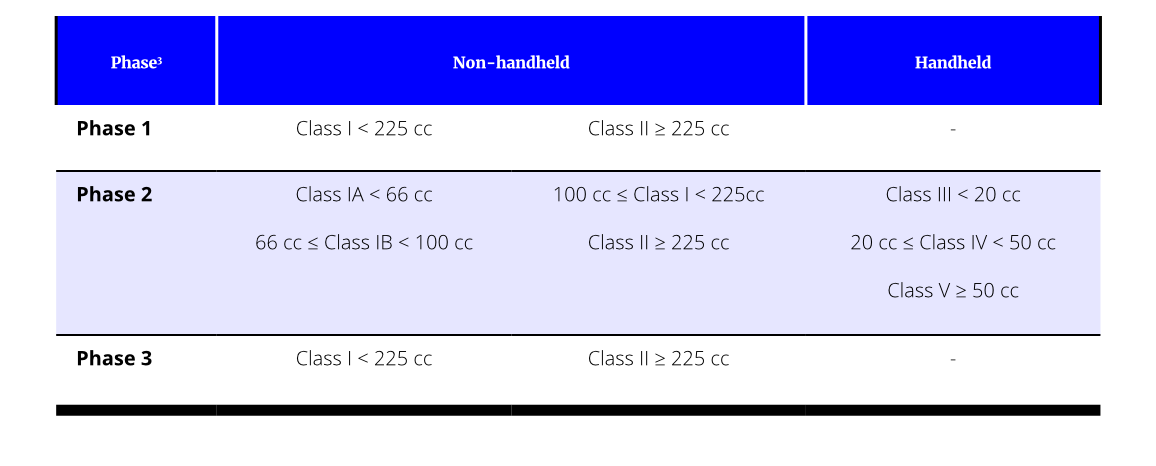

- Spark-ignition combustion engines are classified by class according to the displacement volume of the pistons in units of cubic centimetres (cc) (see Table 4. 3).

TABLE 1

Engine classes according to piston displacement volume.

Source: self made.

/2/

Main regulatory

instruments for NRMM

emissions reduction

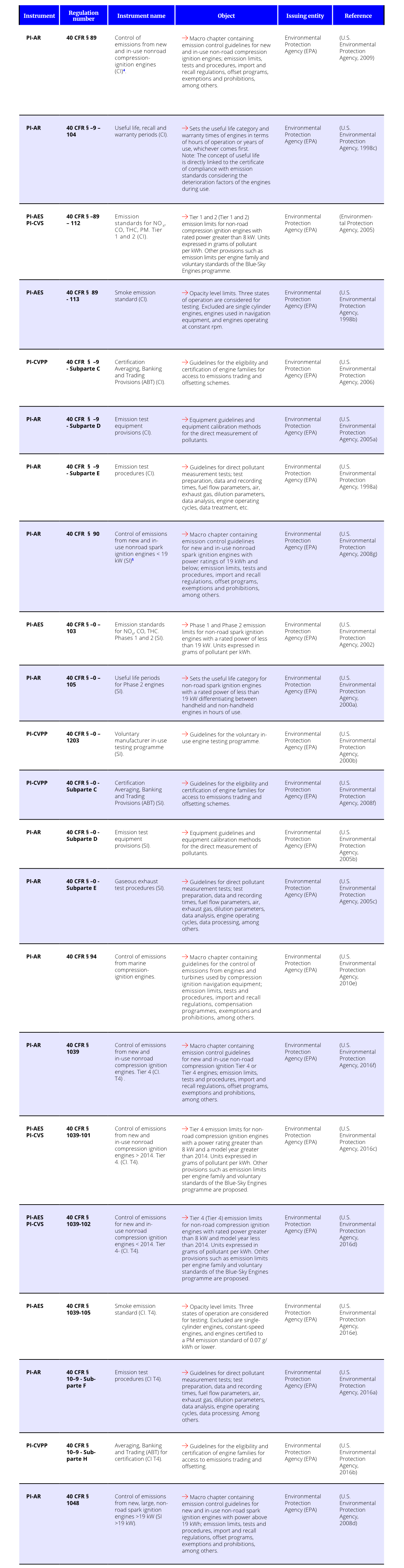

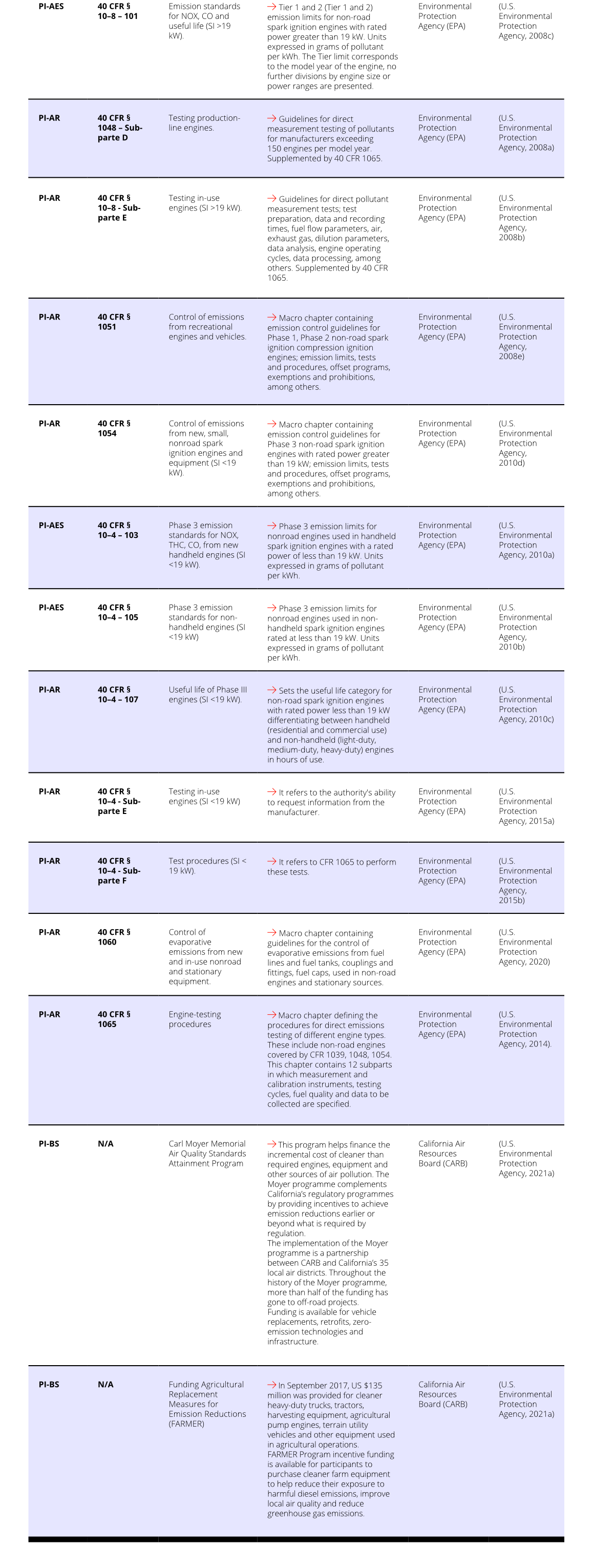

A compilation of different types of instruments identified in the United States for the control of air pollution generated by NRMM is presented in Table 5. 4.

TABLE 2

Regulatory framework and identification of NRMM emission reduction tools – United States.

Source: self made.

There is an initiative supported by the cities of Los Angeles and San Francisco known as the C40 Clean Construction Declaration (C40, 2020), in which Mexico City commits to require zero-emission construction equipment in municipal projects from 2025 and zero-emission construction sites throughout the city by 2030, when available.

/3/

Emission standards

for air pollutants

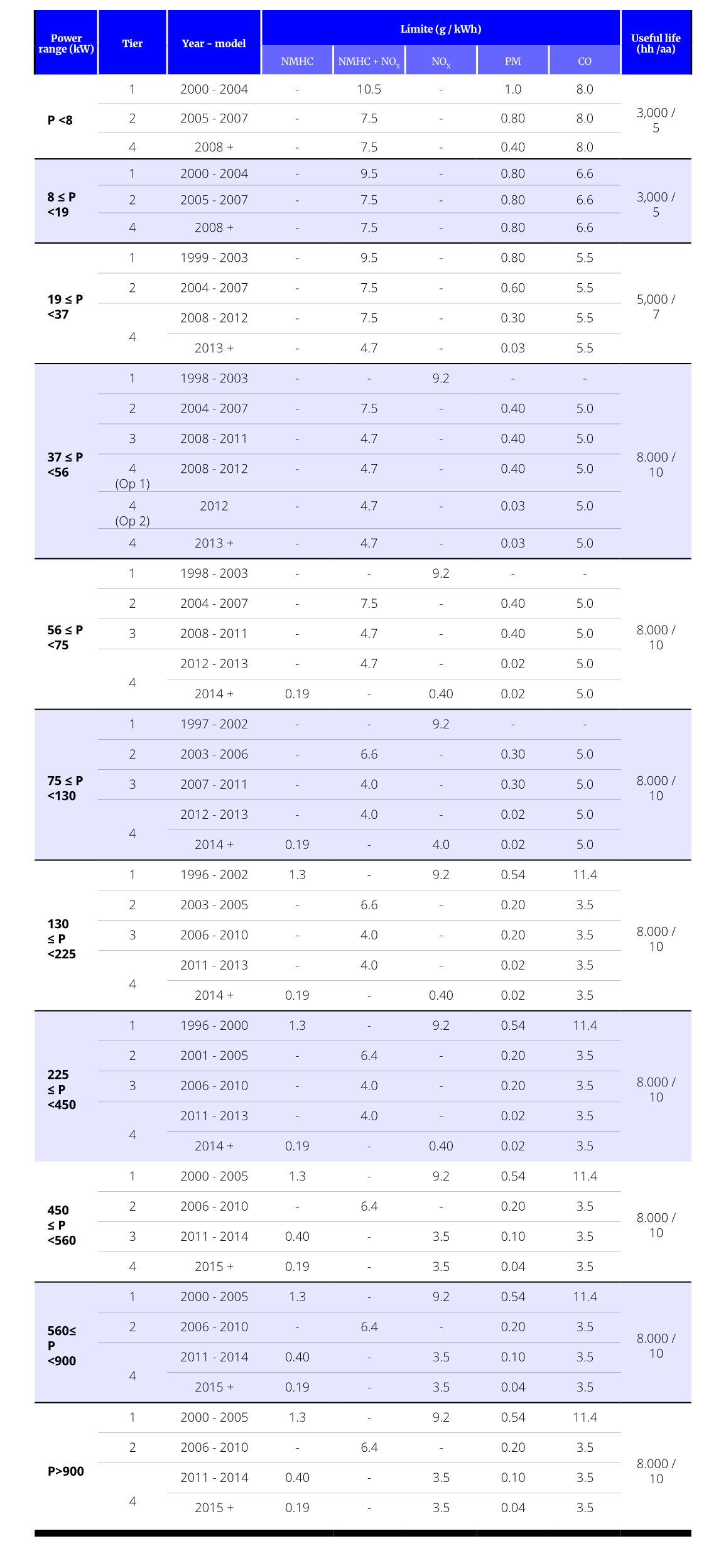

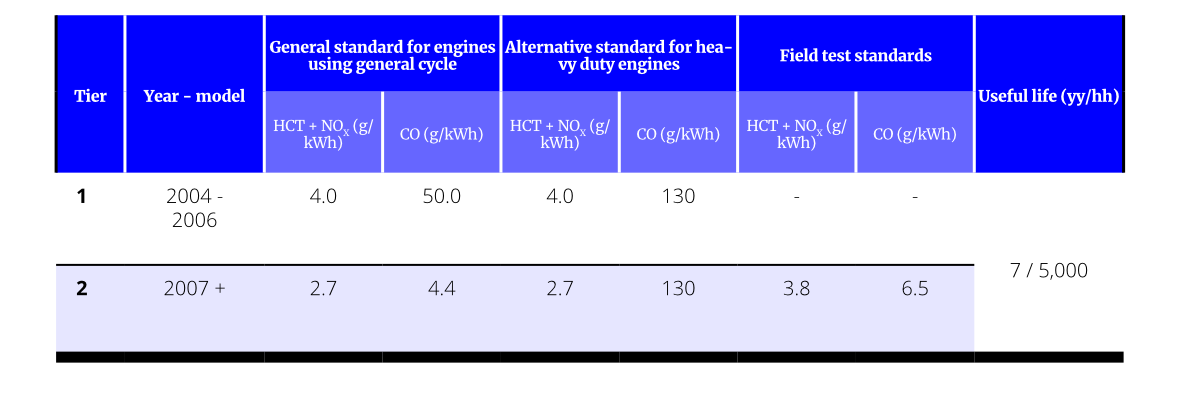

The first regulation related to emission limits (Tier 1) for non-road engines was published in 1994, which would come into force between 1996 and 2000 and covered compression ignition engines with a rated power above 37 kW (Reference Standard: 40 CFR 89). In 1995, emission standards were formulated for non-road spark ignition engines with a rated power below 19 kW at the Tier 1, which were to become effective from 1997. For the same engines, Tier 2 standards were formulated in 1999 and became effective between 2001 and 2007. Tier 2 has a 59% reduction in HC and NOX emissions compared to Tier 1 (United States Department of Agriculture, 2002). Tier 3 standards were formulated in 2008 and come into force between 2011 and 2012.

In 1998, Tier 1 emission limits were defined for compression ignition engines below 37 kW and Tier 2 and Tier 3 emission limits were proposed to be implemented between 2001 and 2006 (Tier 2) and between 2006 and 2008 (Tier 3). The fuel used to certify these standards was diesel with a maximum sulphur content of 2,000 parts per million (ppm) (TransportPolicy.net, 2021). One of the objectives of the Tier 2 and 3 Engines can be imported as certified engines from the United States, or engines installed in certified vehicles. In general, engines that are imported must be covered by a Certificate of Conformity, unless it was built before the date of entry into force of the regulations.. standards was to promote compliance by advancing engine design rather than emission control or gas treatment systems. These standards were primarily aimed at controlling nitrogen oxides and hydrocarbons, not particulate matter (PM); even for various engine categories, Tier 1 had no limits for PM and Tier 2 and 3 have the same values.

In 2004, Tier 4 emission limits for non-road engines were adopted and came into effect between 2008 and 2015. These focused on PM and were up to 90% stricter than the values presented in the Tier 2 and 3 standards. These standards were accompanied by regulations on diesel quality, setting a maximum sulphur content of 15 parts per million (ppm) for 80% of sales in June 2006, and 100% in 2010 (MECA, 2021).

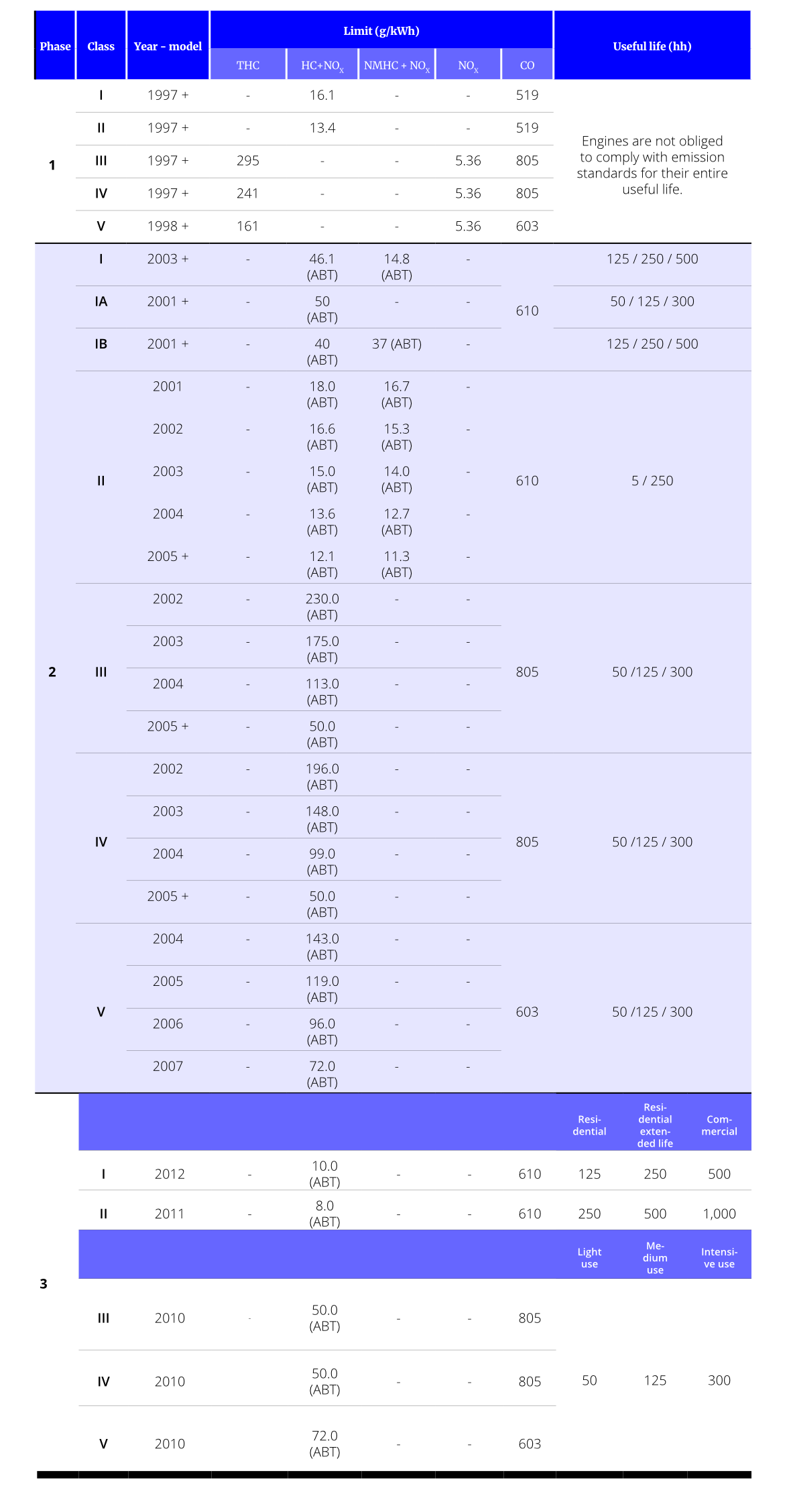

The tables below present the emission standards and useful life periods for the different classifications of engines regulated by the United States. The useful life of engines is established by the length of time the engine has been in operation, either in hours of use or years of age, whichever comes first.

TABLE 3

Emission standards for compression ignition engines

Source: self made.

TABLE 4

Emission standards for spark ignition engines and reference power ≤ 19 kW. ABT: Averaging, banking, trading.

Corresponds to emission offsetting programmes between different engine families or lines, or manufacturers. Averaging refers to the exchange of emission credits between engine families within a given manufacturer´s product line. Banking means the retention of emission credits in a given engine family for use in future models or for the purpose of trading. Trading refers to the exchange of emission credits between engine manufacturers. Emission credits represent the amount of emission reductions or exceedance, by an engine family below or above the applicable emission standard.

Source: self made.

TABLE 5

Emission standards for spark ignition engines and reference power > 19 kW.

Source: self made.

/4/

Import requirements

and type-approval

processes

4.1 Import requirements

The EPA establishes detailed regulatory and admission requirements for stationary and off-road engines (19 CFR§ 12.74) (40 CFR§ 1068.Subpart D).

Importers must file Form 3520-21 and submit the information to EPA’s Office of Transportation and Air Quality (EPA-OTAQ) and keep these documents and media for at least five years after the date of importation Certificate of Conformity (COC): Document that EPA issues to an engine manufacturer (OEM), or importer (ICI), to certify that an engine family meets EPA requirements. There are 10 categories of engines that can be selected in this format. Engines may be imported as certified engines from the United States, or engines installed in certified vehicles. In general, engines that are imported must be covered by a Certificate of Conformity, unless it was built before the effective date of the regulations.

There are two important definitions as to the type of engine being imported and different formalities and procedures depend on this.

- U.S. version engines: These are engines that are manufactured in accordance with federal emission requirements. The manufacturer affixes a label in the engine compartment that indicates, in English, that the vehicle complies with all EPA regulations. A vehicle that lacks the EPA emissions compliance label is considered non-compliant.

- Non-US version engines: These are engines generally sold in foreign countries that do not meet the emission standards set by the EPA.

If the engine in question does not comply with the emissions regulations, it may be imported under certain circumstances on a temporary (40 CFR § 1068.325) or permanent (40 CFR § 1068.315) basis, as explained below.

Temporary: this modality requires the payment of a bond that will remain in the custody of the U.S. Customs and Border Protection until the engine leaves the country again or its destruction is demonstrated.

- Repairs: this modality applies to engines that are temporarily imported for the purpose of being repaired and must be re-exported or shown to have been destroyed. This figure requires the payment of a temporary bond.

- Testing: temporary importation modality for engine testing.

- Display: temporary importation modality for exhibition and sales purposes.

- Export: This modality can be used if the country of export has different emission standards to those stipulated by the United States, in which case it must have a Certificate of Conformity. Otherwise, the engines may be operated only in preparation for the export process.

- Diplomatic or military use: it is possible to import a non-compliant engine if the applicant is a military or governmental entity.

- Delegated assembly: it is possible to import engines that do not comply with the emission standards if it is demonstrated that the missing parts to comply with the standards (e.g., emission control systems) are to be installed by the manufacturer.

- Partially complete engine: this corresponds to the import of an engine that is not finalised and will be modified

Permanent:

- National security: engines for use in military and national defence equipment. They must include a label presenting their emission standard.

- Manufacturer-owned engine: is applicable if the manufacturer (OEM) has at least one Certificate of Conformity. This engine must be used only for manufacturing products, evaluating production methods, and promoting engines in the market. It may not be sold or exchanged.

- Replacement engine: it is permitted to import an engine that is outside the emission standard approval date to replace one that has already been put into service.

- Extraordinary circumstances.

- Hardship for small-volume manufacturers: depending on the circumstances, it is possible to extend the date of compliance with the emission standards for small companies that demonstrate that not importing the engines will put the company’s solvency at risk. Balance sheets and supporting documents must be submitted, as well as action plans to ensure that this does not happen again.

4.2 Type-approval processes

The following definitions are relevant to machinery type-approval processes:

Certificate of Conformity (COC): A document that EPA issues to an engine manufacturer (OEM), or importer (ICI), to certify that an engine family meets EPA requirements. All classes of non-road engines sold in the U.S. are required to have a Certificate of Conformity and are valid for only one model year of production (U.S. Environmental Protection Agency, 2021b).

Engine family: A manufacturer’s (OEM) product line is divided into engine families that are composed of engines expected to have similar emission characteristics during their useful life (40 CFR § 89.116).

Engines and Vehicles Compliance Information System (EV-CIS): is a comprehensive data management system that allows vehicle and engine manufacturers to securely submit required emissions data and other compliance information to EPA. It also contains a subsystem, the Engine and Vehicle Exemption System (EV-ES), which collects basic contact information (name, address, email address, vehicle identification number (VIN) and phone number) from individuals seeking to temporarily import nonconforming vehicles or engines into the US (Regulations.gov, 2021). The Manufacturer must be registered with a unique three-digit alphanumeric code, regardless of whether it produces equipment for different industries.

/5/

Labelling

processes

The manufacturer must affix at the time of manufacture a permanent label and eligible label identifying each non-road engine that is manufactured. Guidelines for engine labelling can be found in 40 CFR § 89.110 and 40 CFR § 1048.135. The label must meet the following requirements:

Assign a unique identification number/4/ to each engine that is manufactured. This must be permanently stamped on the engine.

- Be attached in such a manner that it cannot be removed without destroying or defacing the label.

- Be durable and legible for the entire engine life.

- Be secured to an engine part necessary for normal engine operation and not normally requiring replacement during engine life.

- Be written in English.

- Be located so as to be readily visible to the average person.

The label must contain the following information:

- The heading “Important Engine Information”/5/.

- The full corporate name and trademark of the manufacturer.

- EPA standardised engine family designation.

- Engine displacement.

- Advertised power.

- Emission control system.

- Engine tune-up specifications and adjustments: these should indicate the proper transmission position during tune-up, and accessories (for example, air conditioner), if any, that should be in operation.

- Fuel requirements.

- Date of manufacture (month and year).

- Family emission limits, if applicable.

- The statement “This engine conforms to (model year) U.S. EPA regulations for large non-road compression-ignition engines”/6/.

- Engines belonging to an engine family that have been certified as a constant-speed engine must contain the statement on the label: “constant-speed only”/7/.

- Engines belonging to an engine family that have been certified as a variable-speed engine must contain the statement on the label “variable-speed use”/8/.

- Engines meeting the voluntary standards to be designated as Blue-Sky Series engine must contain the statement.

/6/

Regulation on machinery

useful life, repowering, overhaul and

scrapping practices

The useful life of the engines is established by the time in operation of the engines, either in hours of use or years of age, whichever comes first. In the section on emission standards (see section 6.2), the useful life periods for the different classifications of engines regulated by the United States are presented.

/7/

Operational and road

circulation requirements

(There is no information for United States)

/8/

Procedures for NRMM

control and inspection

in the operation stage

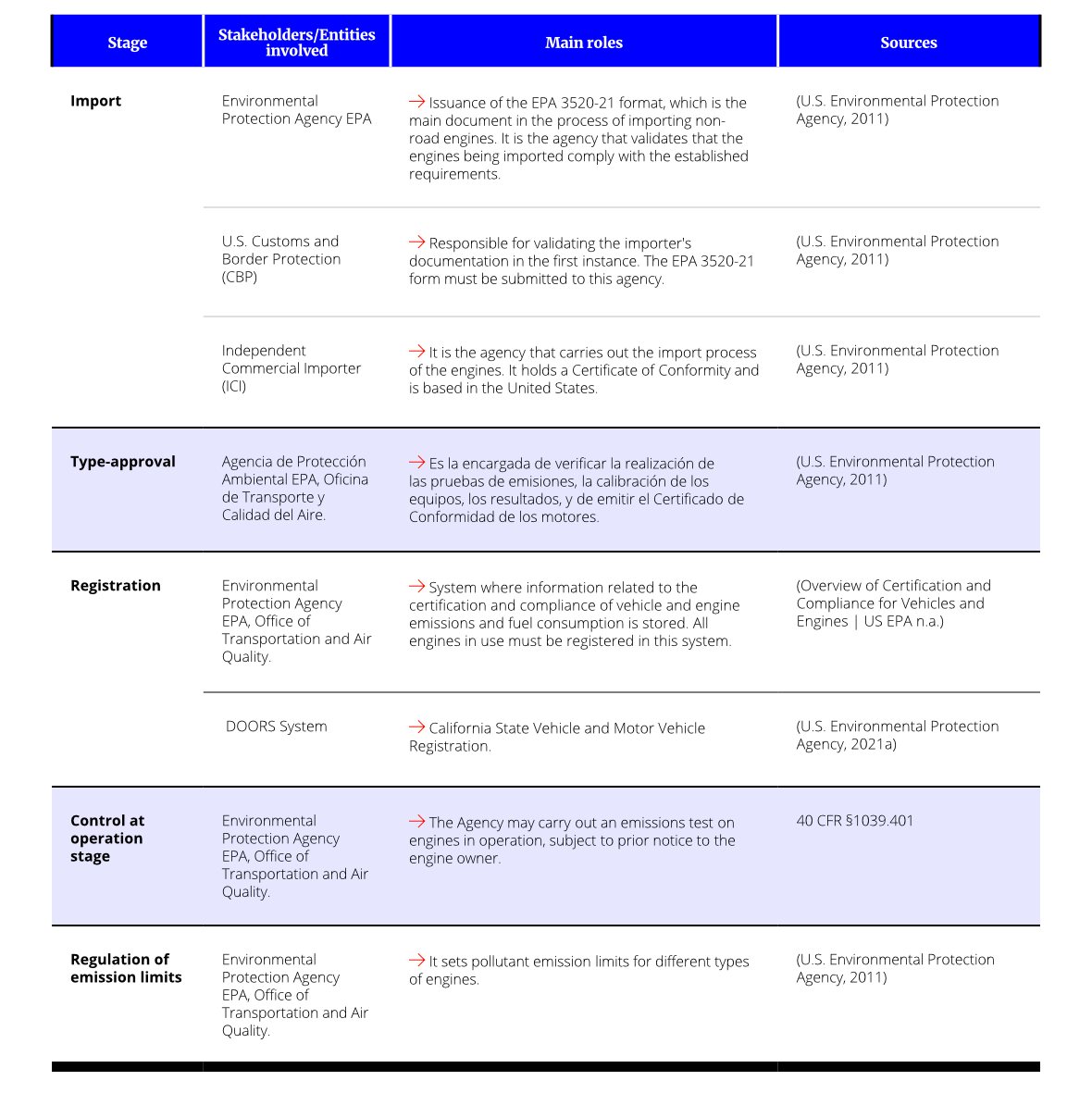

In the United States, no off-road engine inspection practices are identified during the operation of non-road engines. The purpose of the regulations is to ensure that engines leave the factory in compliance with emission limits during their useful operating life. The Certificate of Conformity is issued to the manufacturer and not to the purchaser or user of the machinery.

Regulation 40 CFR § 1068.20 specifies that the Environmental Protection Agency (EPA) may conduct inspections of emissions testing and equipment and their calibration certificates, manufacturing processes, storage warehouses (including seaports), and available documents or records.

/9/

Actors in import processes, manufacturing, registration, marketing, control and final practices of useful life of the MMNC

The table below presents the main stakeholders involved in the NRMM processes in the United States.

TABLE 6

Stakeholders and roles – United States.

Source: self made.

Additional information on the stakeholders involved in each process is presented in the following part.

Import

Customs and Border Protection/9/.

Independent Commercial Importer (ICI): an entity, other than an OEM, located in the United States, on whose name a Certificate of Conformity for a class of non-road engines has been issued, allowing it to import and modify certain nonconforming road engines to meet EPA requirements (U.S. Environmental Protection Agency, 2011). The ICI is not associated with the EPA or the original vehicle manufacturer.

Final purchaser: a person who in good faith buys a non-road engine for an ultimate purpose other than resale.

EPA Administrator: representative of the United States Environmental Protection Agency (US-EPA).

Manufacturing

Original Engine Manufacturer (OEM): the entity which originally manufactured the non-road engine (40 CFR § 89.602).

Secondary Engine Manufacturer: the entity that produces a new engine by modifying a complete or partially complete engine that was made by a different company (40 CFR §1068.30).

Registration

EPA-OTAQ: US-EPA Office of Transportation and Air Quality.

DOORS system: In the state of California, owners must report the fleet acquired within 30 days after purchasing it through the DOORS system. Also, not only new vehicles must be registered through this platform, but also those that have been sold and decommissioned. The owner companies must submit an annual report every March.

Consultation documents (downloadable)

Formato de importación