Executive summary

Executive summary

Introduction

This information gathering and analysis aims to strengthen the knowledge on existing practices for regulating non-road mobile machinery (NRMM) emissions. The experience of the European Union and 14 other countries was compiled in order to provide examples of strategies that can be useful for developing instruments that can significantly reduce pollutant and greenhouse gas emissions in the Region.

The formulation of policies and other regulatory instruments to reduce NRMM emissions is a relatively new issue in several regions of the world. This review, in addition to presenting the emission standards that apply in different countries, includes aspects of machinery regulation throughout its life cycle, such as import/manufacture, registration, sale, operation, scrapping, etc. Through this holistic information gathering approach it is also possible to identify potential inter-institutional synergies within the countries in terms of verification, inspection and control of machinery emissions.

The information gathering methodology focused on existing regulations for each case study, covering environmental, transport and trade sector regulations, among others. Previous studies from indexed literature and the community of practice were also reviewed, as well as interviews with independent public and private sector stakeholders.

Information structure

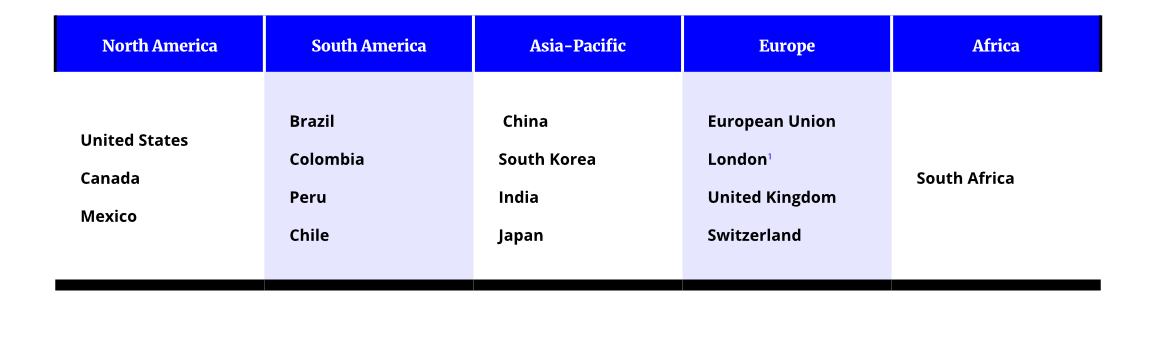

Information compilation and analysis was divided into 10 (ten) sections gathering the information found for each of the geographic areas under study, as shown below:

TABLE 1

Case studies

Source: own elaboration.

Among the countries selected for analysis are those with the most advanced policies for internal combustion engine machinery.

For terminology purposes, the international term “non-road mobile machinery” (non-road) is used in this document. However, in those cases where the regulation of a country or region uses the term “off-road”, this term is maintained in accordance with the terminology used in those cases.

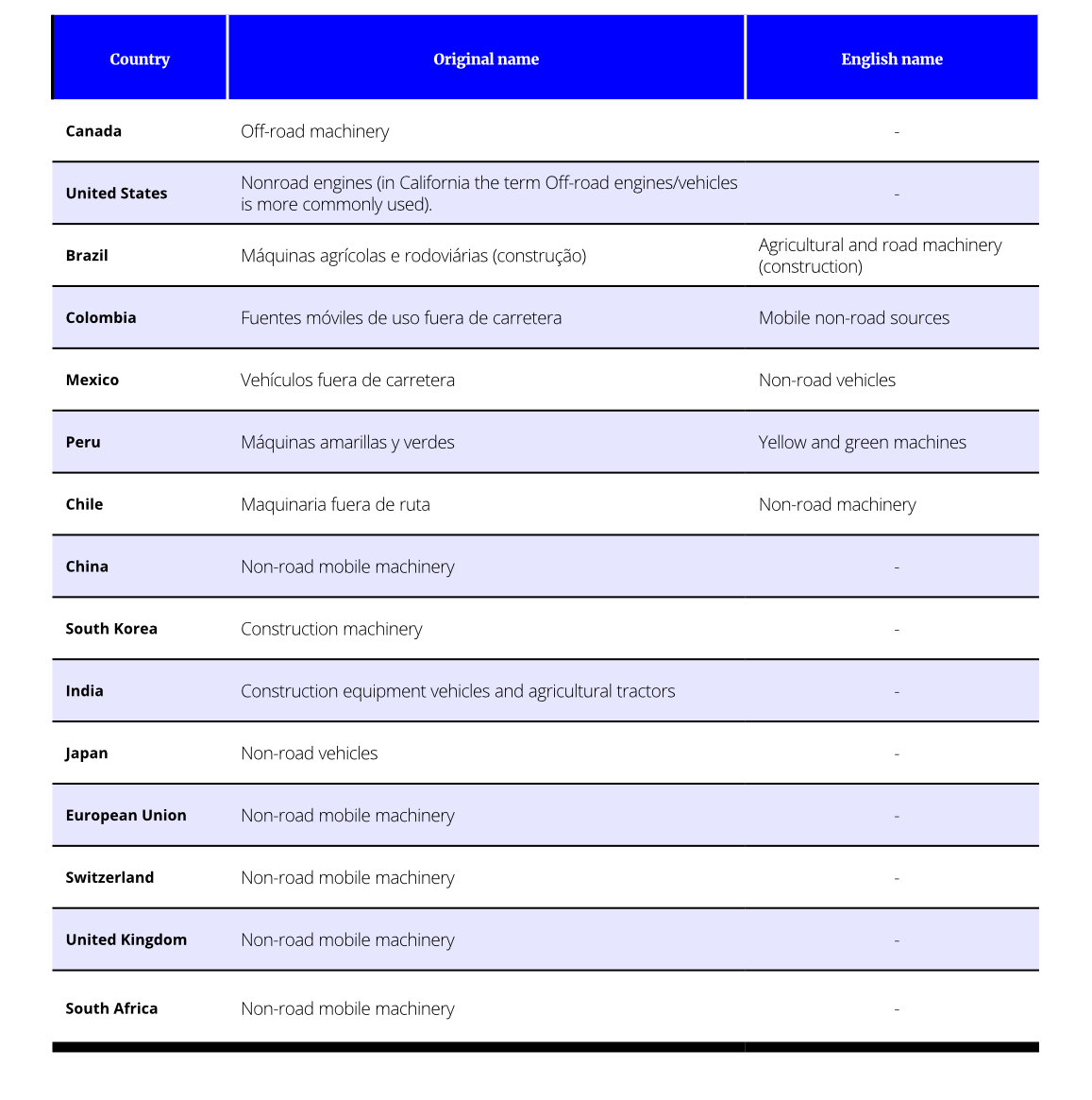

TABLE 2

Terminology used to refer to machinery in the different case studies

*El campo Traducción oficial al español hace referencia a la existencia de la normativa en español. En los casos en los que no se cuenta con el nombre oficial en español se presenta una traducción.

Source: own elaboration.

For each of the countries, the information was analysed in the following areas.

- Definitions of Non-Road Mobile Machinery (NRMM).

- Identification of local pollutant reduction tools for non-road mobile machinery.

- Air pollutant emission standards

- Import requirements and type-approval processes

- Labelling processes

- Regulation on machinery useful life, repowering, overhaul and scrapping practices

- Operational and road circulation requirements

- Procedures for NRMM control and inspection in the operation stage

- Stakeholders involved in the import, manufacturing, registration, sale, inspection and end-of-life practices of NRMM

The definition of NRMM, especially in a legal context, is important as it outlines the nature of the sources to be regulated. It is also important to identify whether the subject of emission regulation is non-road mobile machinery and/or specifically the machinery engines. In terms of air emissions, it is primarily the engines contained in the machinery that are regulated according to their power. However, the definitions of NRMM must be known and considered.

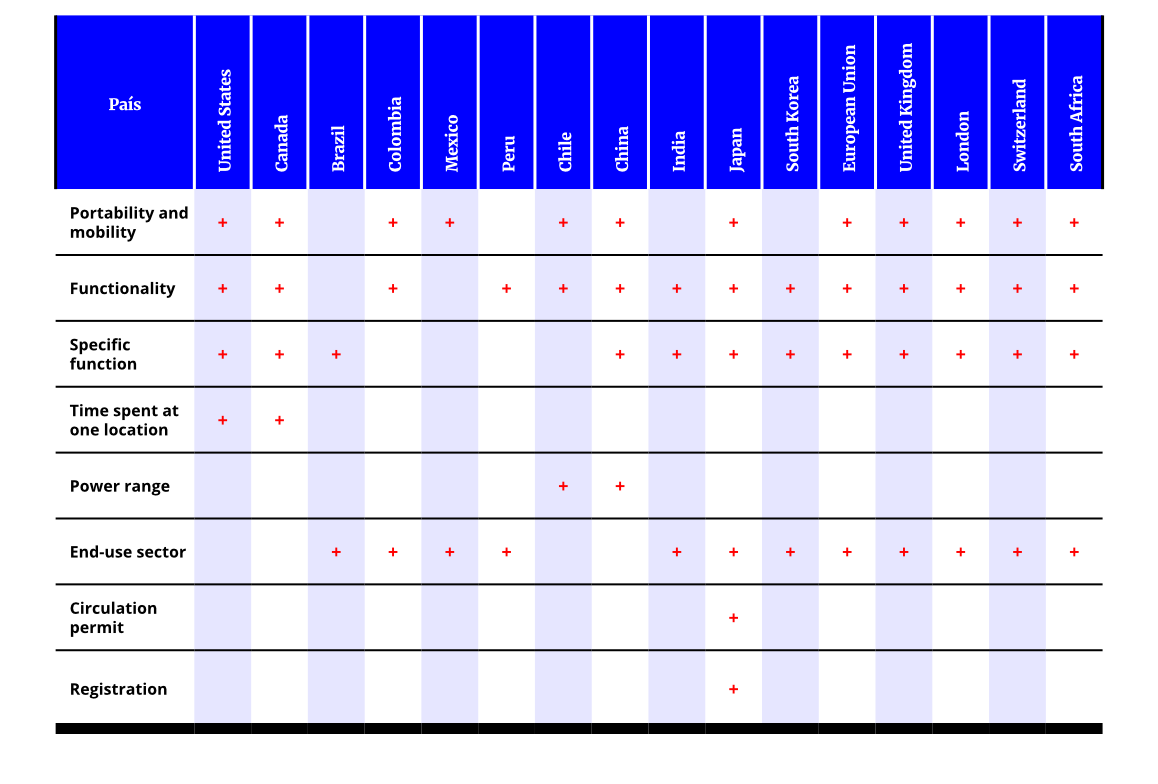

Eight predominant criteria were identified, the most common being: (i) portability and mobility, which refer to whether the vehicle or machinery in question is part of self-propelled equipment, is handheld or portable; (ii) end-use sector, which refers to inclusion or exclusion in the NRMM category depending on the sector where the vehicle or machine is used; iii) functionality, which means that the vehicle and machine´s main use is different from the transport of persons or goods; and iv) specific function, which are cases where a list of machinery and vehicles with their functions is provided and it is specified that they are part of the NRMM category (see Table 2.3).

TABLE 3

Criteria used to define NRMM in the case studies

Source: own elaboration.

A review was carried out of different instruments used to control NRMM emissions and other processes associated with the life cycles of machinery, such as transport, safety and other areas. The latter, as instruments of potential indirect utility to reduce emissions by facilitating the surveillance, control and inspection of emission sources.

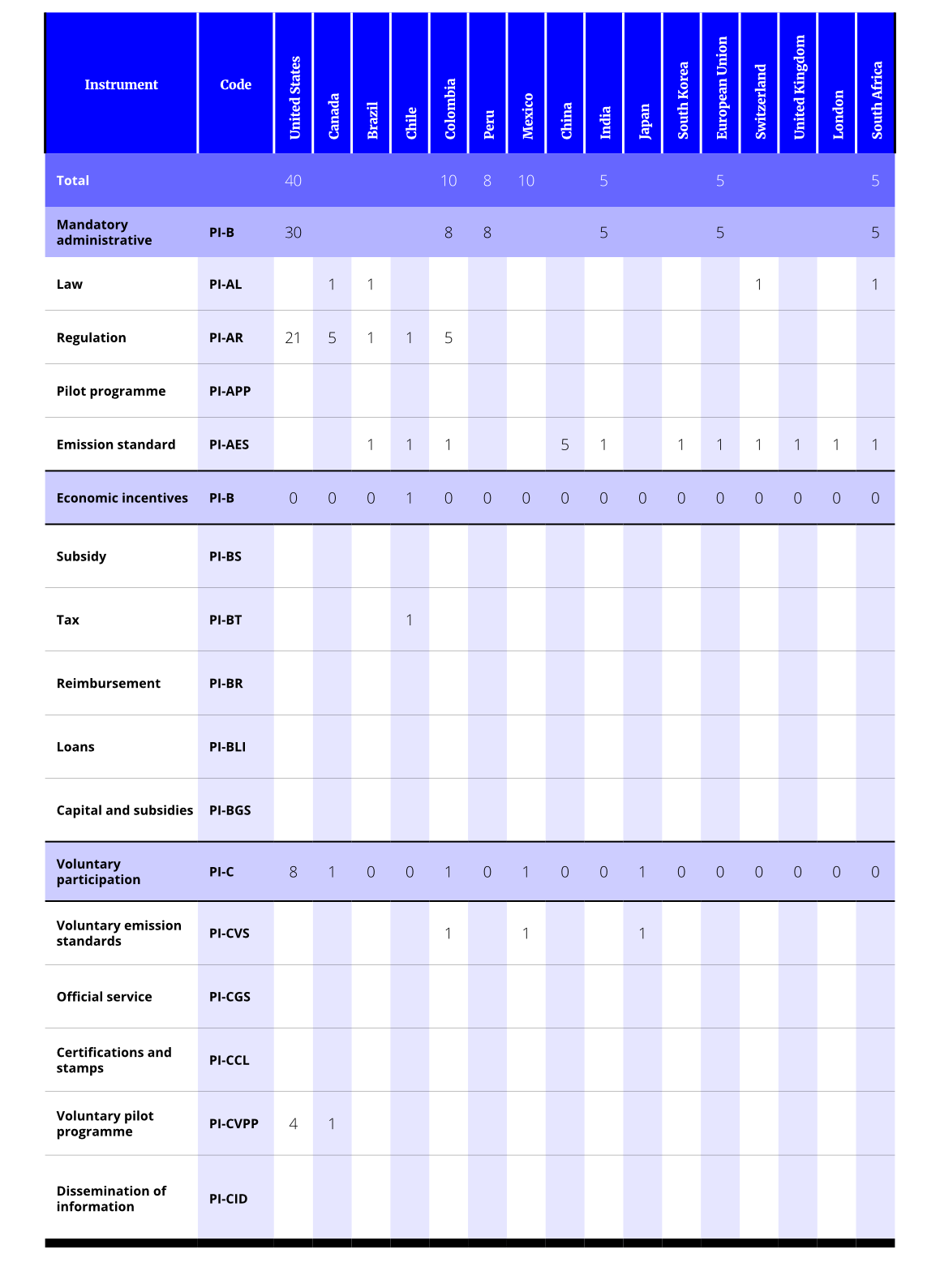

The instruments were classified into three groups, according to the methodology employed by Huang et al., (2021): 1) Mandatory Administrative Instruments, 2) Economic Incentive Instruments and 3) Voluntary Participation Instruments. The regulatory instruments cited in the information review document were kept on file for consultation by any interested party. As a result of this grouping, it became evident that most of the instruments belong to the mandatory administrative group, followed by the voluntary participation instruments and in last place are the economic incentives.

Following Huang et al., (2021) and several other authors, it is recognised that the most effective strategies for regulating pollutant emissions are those that combine different types of instruments (mandatory, economic incentives and voluntary). However, in practice, it is evident that there is a predominant reliance on mandatory instruments to achieve emission reductions.

TABLE 4

Number of emission reduction instruments identified per case study.

Source: own elaboration.

In terms of regulation of emission levels, it was found that of the countries with such standards, all have emission limits for particulate matter, nitrogen oxides, hydrocarbons and carbon monoxide. Countries such as China, India and the European Union also have regulations that are beginning to incorporate particle number (PN) standards. The regulatory schemes identified contain mostly emission standards for new emission sources to be imported, manufactured and sold in the countries and, to a lesser extent, instruments for machinery in use. For the latter sources, it was found that the most widely implemented aftertreatment system for the reduction of particulate matter from in-use machinery is the diesel particulate filter (DPF).

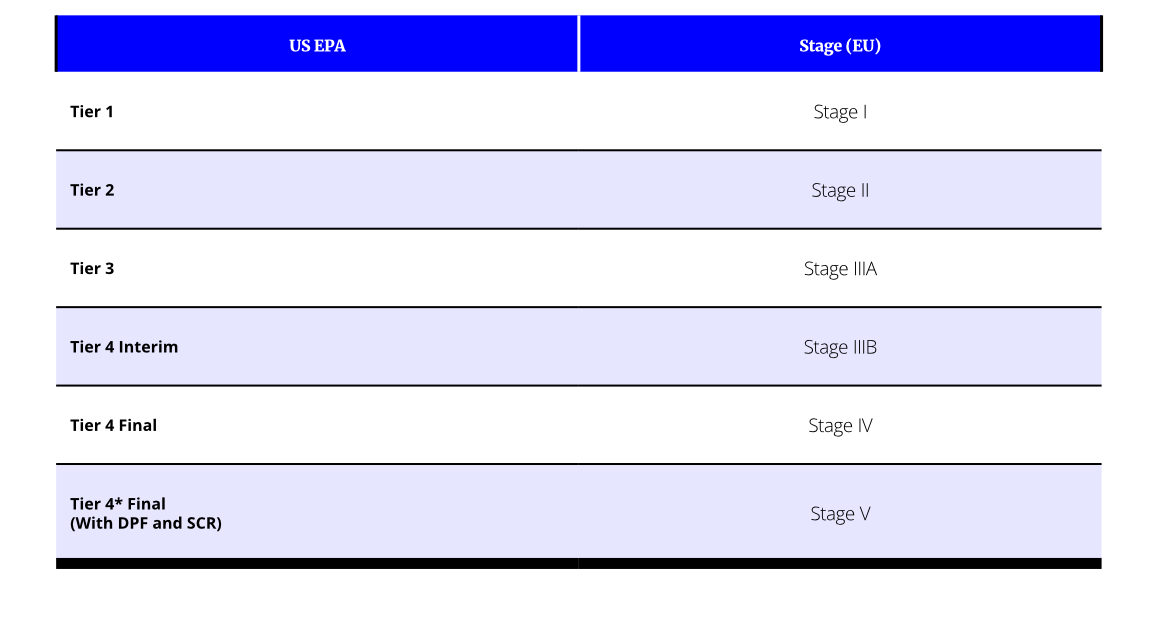

For the group of countries that have emission level limits, the gradual adoption of the standards for the period 1996-2021 was reviewed (see Table 2.5). The emission levels mentioned below are those that the community of practice has largely adopted in the different countries of the world, which are primarily based on the regulations of the European Community and the United States. For practical purposes and given their similarities, it is possible to establish equivalence between these emission standards:

TABLE 5

Emission Standard Equivalences

* There is no standard equivalent for Stage V, but could be considered emissions equivalent in terms of control systems if Tier 4 Final is met by implementing DPF and SCR filters.

Source: CALAC+ 2021

The United States was the first country to implement emission limits for NRMM, and this case also stands out because from the outset it implemented limits covering all power ranges of machinery. The countries with the most advanced and currently implemented emission standards are the EU countries with Stage V standards, followed by the USA with Tier 4 Final and Korea, Japan and India with Stage IV.

Overall Evolution of Machinery Emission Reductions for US and European Standards

Source: Cited by Tampere University of Technology/3/

In terms of standards in the pipeline, China has recently enacted regulations that will apply highly stringent emission standards in the coming years. The standards applicable to machinery were updated in 2020, requiring that from December 2022 Stage IIIB emission standards will come into force with some requirements of the European Stage V standard such as particle number (PN) limit. For the latter, the installation of GPS in machinery is anticipated, as well as control with on-board emission monitoring systems (PEMS), among others, to evaluate compliance with the permitted standards (ICCT, 2021).

In Latin America, so far Brazil has Stage IIIA emission standards; in the case of Chile, on 21 October 2021 a Supreme Decree was published that establishes the emissions standard equivalent to Stage IV or V standard for machinery to be brought into the country, applicable 24 months from the entry into force of the standard; agricultural tractors have 36 months to comply with this requirement6. At the local level, the Plan de prevención y descontaminación atmosférica para la región metropolitana de Santiago (Air Pollution Prevention and Decontamination Plan for the Metropolitan Region of Santiago) includes requirements for the implementation of DPF particulate filters for machinery with power ranges between 56 kW and 560 kW.

Colombia is working on a bill7 for machinery emission standards that calls for the implementation of Stage IIIB standards for units to be imported into the country in the coming years. Locally, the city of Bogota has developed the Plan estratégico para la gestión integral de la calidad del aire a 2030 (Strategic Plan for the integrated management of air quality to 2030), which includes measures aimed at promoting the technological upgrading of construction machinery operating in the city. In Mexico, the Metropolitan Area of the Valley of Mexico (including Mexico City) has published the Programa de gestión para mejorar la calidad del aire PROAIRE 2021 – 2030 (Management Programme to Improve Air Quality PROAIRE 2021 – 2030), which includes machinery emissions and highlights the need for a standard to regulate emissions from these sources. In Peru, actions related to the quantification of machinery engine emissions in inventories and the need to set regulations on emission limits were included in the Plan de acción para el mejoramiento de la calidad del aire de Lima-Callao 2021-2025 (Action Plan for the Improvement of Air Quality in Lima-Callao 2021-2025)8.

The comprehensive analysis of policy and regulatory instruments also identified experiences with machinery labelling, operation and road circulation requirements, control and inspection procedures and the main stakeholders involved in these processes. According to the case review, emission control and inspection processes are generally focused on the production, import and type-approval stages of NRMM. Switzerland is a special case as the control of the machinery distributed in the country is carried out based on the market information of the machinery, i.e., an internal control mechanism in which the authority checks this information with the private counterparts. On the other hand, when searching for information in the countries consulted, the machinery registration processes were highlighted as important, as they play a strategic role in the inspection of NRMM.

A wide variety of aspects were identified in the operation and road circulation requirements of NRMM that are included in the regulation. These may be broadly classified into environmental requirements, related to emission levels of air pollutants and noise; and safety requirements, which are the most common and include aspects such as speed of circulation, zones where NRMM is allowed to circulate, hours of circulation, ways to move machinery between sites, licensing and training requirements for operators.

In the United States, Canada, Brazil, the European Union, China and the United States of America, guidelines are provided in the NRMM regulation covering at least one of the aspects of machinery end-of-life (NRMM useful life, repowering, overhaul and scrapping practices). In cases such as the United States, the European Union, Canada and China, regulation is associated with the control of air pollutant emission levels and the emission assessment considers the deterioration of the emission control systems of machinery over its lifetime.

It should be noted that there are mechanisms to control emissions during the NRMM operation. For example, in the European Union, starting with Stage V, through an in-service compliance mechanism for certain power ranges that considers testing pollutant emissions of a sample of machines during the first years of their useful life (Directive 2017/0655).

Emission verification mechanisms for in-use machinery focus on opacity measurements; particle number measurements are also carried out in cases where the machinery is fitted with a diesel particulate filter (DPF). Regarding the latter control system, it is found to be the preferred and most effective emission control strategy for reducing particulate matter emissions from in-use machinery, with Switzerland being one of the first countries to establish regulations in this respect, applicable since the 1990s.

TABLE 6

Comparison of emission standards for non-road mobile machinery around the world 4

* Equivalencia entre kW y HP: 1.34 HP = 1 kW.

Note: The maximum net power used in China refers to the maximum value of the net power on the full-load rated power curve for the engine type, unlike in Europe, where emission limits are reported according to a reference power that may correspond to the maximum net power or the manufacturer’s declared net rated power of an engine at rated speed, as specified for each category of non-road mobile machinery engine. Rated speed refers to the maximum engine speed at full load allowed by an engine´s governor, as designed by the manufacturer or, in the absence of a governor, the speed at which the maximum net power output is attained by the engine, as specified by the manufacturer. (REGULATION (EU) 2016/1628 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 14 September 2016 on Requirements Relating to Gaseous and Particulate Pollutant Emission Limits and Type-Approval for Internal Combustion Engines for Non-Road Mobile Machinery, Ame, 2016).

**Broad equivalence Bharat (CEV) Stage IV and Bharat (Trem) Stage IV. For India, the entries into force and some maximum permissible levels vary depending on the industry in which the machinery operates. Some Bharat standards are not related to US standards, nor to European standards; in these cases, they are represented in the table with the colour of the standard that the machine would meet. For example, machines below 19 kW rated under Bharat (Trem) Stage III meet the Tier 1 standard, but not Tier 2.

4 Note: The years of entry into force indicated here correspond to the most representative dates for the power ranges. However, for some categories, e.g., agricultural machinery, the dates of entry into force may be later than those indicated here as they have had a special deadline. Therefore, this table should be used only as a general indicator and for details of the exact dates (year and month) of entry into force of a particular machine it is important to refer to the original standard, power range, category and other characteristics to identify the corresponding table.

Source: Elaborated by CALAC+, 2020a

In 2020, the Chinese government updated the emission standards for NRMM. The new standards, to be implemented in December 2022, will be equivalent to Stage IIIB limits but upgraded to meet some requirements of the Euro Stage V standards (ICCT, 2021). This analysis is available at: https://theicct.org/publications/china-iv-non-road-emission-standards-jul2021.

Based on the characterisation of the NRMM regulation from different case studies, some practices are identified that could be used as a reference for NRMM emissions control in Latin America. Some of these practices are mentioned below:

- The US, EU, Switzerland and UK have established engine-based regulations which favours the development of concise and practical instruments for classifying types of NRMM. This perspective reduces the risk of loopholes compared to an emission regulation based on machinery typologies. For Latin America, these strategies can be taken in combination with some of the criteria for defining NRMMs, in order to establish effective control and follow-up mechanisms for the standards to be proposed.

- In Switzerland, at the federal level, the control and inspection of machinery is carried out on the basis of commercial information that the private sector is able to provide at the request of the Federal Office for the Environment. In addition, the cantons (states that make up the Swiss Federation) have the power to establish their own complementary control mechanisms. These can be varied and include site visits, emission measurements, among others.

- Emission regulation for NRMM is mostly focused on the implementation of emission standards for new machinery fleets; however, natural machinery replacements are slow processes that can take several decades and for this reason, it is advisable to implement short-term machinery emission control strategies on existing fleets. The Swiss experience is highlighted here as a global pioneer since the 1990s in implementing DPF filter policies for the reduction of particulate matter in in-use machinery.

- The guidance of the European Union and the United States towards emission controls at the manufacturing stage of engines and certification tests that guarantee emission levels that comply with the regulation during their useful life is highlighted. In this regard, manufacturers –and not only the user of the machinery– are responsible for emissions. This approach poses the challenge of guaranteeing emission standards during the time of use for which the emission certificate was issued (useful life).

- The State of California has implemented the DOORS platform for machinery owners to register the equipment purchased and scrapped each year, allowing them to monitor the operation time of the machinery. This is a model with defined roles and responsibilities to track machinery from its manufacture, usage time and its final disposal or need for overhaul.

- There is synergy between NRMM pollution reduction and other environmental programmes. This can be achieved by linking NRMM regulation with established national or local air quality programmes (e.g., Asia-Pacific and India), as well as with greenhouse gas emission mitigation programmes.

As a complementary aspect to the documentary reviews, interviews were carried out with government stakeholders, private sector consultants and machinery importing companies in the countries targeted by the CALAC+ programme, and the main aspects were identified as follows:

- Effective regulation of NRMM emission limits must be accompanied by programmes on best practices in machinery operation and maintenance.

- Other instruments that can also contribute to reducing NRMM pollution include local decontamination plans, implementation of sustainable building standards, private sector sustainability plans and greenhouse gas emission reduction targets.

- The operation and inspection of machinery could be more efficient if linked to construction permits issued by local or state authorities for their works.

- The specifics of each sector that uses machinery (construction, mining, industry, agriculture, forestry) should be considered in order to establish the regulatory framework for NRMM according to its context and impact. There are sectors in which regulatory prioritization is necessary due to the high levels of exposure for the operating personnel or for the population around the area of influence of NRMM emissions. For example, it is possible to make exclusions for social and/or economic reasons, as is the case for the agricultural sector in several of the cases analysed.

- The private sector has a key role in reducing air pollution generated by NRMM. It can be a leader in the implementation of socially and environmentally responsible practices, by anticipating and cooperating with the public sector. These practices can in turn be encouraged and recognised by the public sector as they are currently being implemented.

Finally, the potential for collaboration in Latin America to develop instruments for the control of NRMM emissions is highlighted. Joint working schemes allow to take advantage of lessons learned in different countries. In addition, joining the efforts of the community of practice in the region is an effective way to overcome some of the limitations of individual countries.